Business has been booming at Vandalia, IL-based OctoChem, a specialty chemical supplier that provides sample fulfillment services to some of the largest companies in the chemical, food ingredient, and biopharmaceutical industries. While OctoChem’s customers typically distribute drums of chemicals in large quantities, they are not set up to handle small sample orders of a gallon or less. That’s where OctoChem steps in, relieving its customers of the logistics involved in fulfilling small orders and keeping track of them after shipping.

OctoChem handles all operations of chemical fulfillment—from fabrication to packaging to shipping to tracking. It ships a wide range of chemical products, from vitamins, caffeine, and other food ingredients to paint pigments and additives to cosmetic products. OctoChem’s growing life sciences division also supports biotechnology companies with similar services.

OctoChem’s value proposition is the ability to quickly package and ship small samples of chemical products to companies around the world—in most cases overnight. Nearly 98% of all orders received are processed and shipped the same day, even for orders that come in late in the day.

“On any given day we might be shipping 1,600 different products to 750 different places around the world,” says Mark Langston, OctoChem’s president.

In order to work at peak efficiency, OctoChem’s packaging and labeling operations need to function flawlessly, and this is where the company identified a weak link in its logistics chain. It was relying on a combination of pre-printed color label stocks and monochrome thermal transfer printers to produce finished labels. With hundreds of different products of varying sizes and pre-printed graphics requirements to ship, it was becoming a logistical nightmare for the company to keep labels in inventory for each of the products.

In addition, as a chemical supplier OctoChem also needs to ensure that its package labels comply with the Global Harmonized System of Labeling (GHS), which among other requirements mandates color labels.

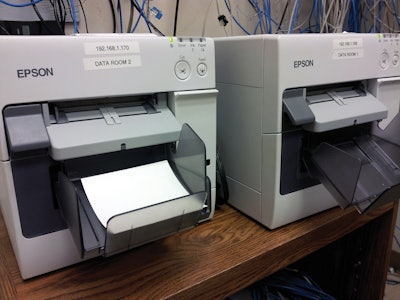

OctoChem discovered a solution to its dilemma by investing in on-demand color labeling using the Epson® ColorWorks™ C3400 label printer. Rather than rely on pre-printed labels and thermal transfer printers, the new printer enables OctoChem to produce color labels at speeds up to 3.7 in. per sec in one step. The company now has only four blank label stocks to handle labeling of some 12,000 unique products.

“We have an on-demand business, and it was a marriage made in heaven when it comes to what this little printer does for us,” Langston says.

For printing, OctoChem accesses its customers’ SAP software to produce a label using MS-Word. Since labels come directly from customers, OctoChem needs to convert labels internally before printing them out. Using SAP software ensures that information on the labels is up-to-date, which is especially critical for transporting time-sensitive chemical products. The label media OctoChem uses is a 3.7 mil polyolefin inkjet label with permanent adhesive.

Another advantage offered by the printer is its ability to easily convert labels to different sizes. “Often we face the challenge of getting huge labels from our customers, for example ones that are 8-1/2 by 11 in. That’s definitely not going to fit on a four ounce product that we’re shipping, so part of our process involves converting these labels down to size. The Epson printer makes it easy to create the label size we need,” Langston says.

OctoChem started beta-testing the printer last year and has since added five additional printers to its operations. The company plans to purchase four or five more printers within the next year as shipping volumes increase and it phases out its thermal transfer printers.

Easy access to color has been another key advantage for OctoChem. In addition to incorporating colorful customer logos on labels, the use of color has helped OctoChem comply with GHS regulations, which are becoming increasingly critical in shipping chemicals. GHS requires chemical shipments to be packaged with durable label media, complete with color icons that clearly spell out potential hazards and important warnings that are consistent with international standards. While the deadline to comply for shipping pure chemical products within the U.S. is not until 2015, the deadlines are three years earlier for Asia and Europe.

“We ship 60 to 70 products to Europe every day on average, so GHS compliance is important to us,” Langston says.

While Langston admits it is difficult to put a dollar figure on the savings the new printers have yielded, the streamlined labeling operations speak volumes to his business. “We’ve seen an across-the-board significant improvement in efficiency by moving to on-demand labels,” he says. “The key value is the time savings to create different labels.”

Increasing efficiency is helping OctoChem meet demands from rising business volume. Beginning operations in 1995, OctoChem broke ground on expanding its manufacturing facilities in southern Illinois in March 2007, and over the last three years the company has seen an average growth of 30% to 40%. OctoChem plans to invest more than $2.8 million to expand its Vandalia, IL, campus and add up to 25 jobs. As part of the expansion, OctoChem will add new warehousing, specialty storage, and production areas, as well as a fully functional laboratory. This is the third major expansion for OctoChem in Vandalia since 2003, in addition to new offices and expanded cold storage facilities.

“We are very excited to be announcing this major expansion of our facilities, which is possible because of our strong growth in global markets,” Langston said. “The Sample Management business is a growing part of OctoChem, and because of the demand for these services throughout the world we are able to add new jobs here. We didn’t build our reputation on being inflexible or slow; our customers know we are able to solve problems quickly. It’s all about speed—and on demand solutions help us meet our goals.”