Specialty Blends is a beverage producer famous for two things: Bob’s Pickle Pops, which are frozen dill pickle ice pops packaged on a stick-pack machine, and Bob’s Pickle Potion, a dill pickle sports drink available in both 3-oz PET and 6.3-oz (187-mL) PET bottles. The Dripping Falls, Texas, firm has seen steady growth since its founding in 1998. But in 2024 the firm partnered with Austin-based Beverage Ranch LLC to launch Slamzees, a 15% ABV “party drink” in brightly decorated 6.3-oz single-serve PET containers. With sales across the board rising briskly, the firm had little choice but to add a new packaging line.

“The main driver behind the new line was definitely Slamzees,” says Nick Tindol, who oversees operations at the Texas plant. “It's a high-alcohol-content, flavor-forward, wine-based cocktail product in a single-serve format with a resealable lid. It’s big on convenience, which is why it’s grown the way it has in convenience stores.”

Also boosting sales considerably is that the product is now available at Walmart stores. All of which led to the need for faster, more automated packaging capabilities. “We’re pretty much nationwide in distribution at this point, so relying on a 12-head in-line filler and manual tray set-up and loading was really holding us back. With eight operators we could do about 50 containers per minute. Now with the new line running, we’re at 150 per minute with six or seven operators. And with the smaller 3-oz pickle juice shot, we can do 200/min.” Since Specialty Blends runs three different bottle widths, these lanes feeding the tray former and packer need to be adjusted, and a patented single-point adjustment feature makes it possible to do this by simply turning an adjustment wheel.Specialty Blends

Since Specialty Blends runs three different bottle widths, these lanes feeding the tray former and packer need to be adjusted, and a patented single-point adjustment feature makes it possible to do this by simply turning an adjustment wheel.Specialty Blends

The benefits of automation are perhaps most notable in the corrugated tray packing and wrapping operation. As Tindol mentioned, what used to happen is a team of operators would manually erect the tray, load in the required number of containers by hand, and then send the filled tray through a semi-automatic L-bar sealer. All of this has been replaced by an automated solution from Polypack consisting of a Model TR-I tray former/packer and a Model IL-24 shrink wrap machine.

“This new system will increase our production capacity by roughly three times, allowing us to fulfill more orders as we expand into additional grocery and convenience retailers,” says Tindol. “It has made our operations more efficient and consistent, while also improving the look and uniformity of our packaging and driving long-term cost savings for our business.” The PET containers are fed into the line by this versatile unscrambler.Specialty Blends

The PET containers are fed into the line by this versatile unscrambler.Specialty Blends

Starts with unscrambling

While the Polypack equipment handles end-of-line duties, the new line begins upstream with a Model AU-6-E unscrambler from Kaps-All. It has a low-profile 36-in. diameter stainless-steel pre-feeder with one inner disc for optimal performance, an exclusive patented design that eliminates the need for numerous change parts. It also has a fully adjustable orienting mechanism capable of handling a wide range of container shapes. That means minimal changeover parts are required for processing round, square, rectangular, or oval containers. Slamzees are round and Pickle Potions are square, so this versatile unscrambler is a great fit at Specialty Blends.

Speaking of bottle shapes, it’s worth mentioning that while the 3-oz shot comes in a stock bottle, the other two PET bottles are custom molds. The 6.3-oz squared-off Pickle Potion bottle comes from TricorBraun, and the 6.3-oz round Slamzees bottle comes from Berlin Packaging. As bottles exit the unscrambler this laser coder puts date and lot code information on the bottom of each bottle.Specialty Blends

As bottles exit the unscrambler this laser coder puts date and lot code information on the bottom of each bottle.Specialty Blends

Bottles arrive in bulk corrugated shippers that are dumped into the hopper of the Kaps-All unscrambler. Before exiting the unscrambler, two things happen. First, the bottle interiors are cleaned with deionized air that is vacuumed out. Second, a laser coder from Macsa ID date codes the bottom of each bottle. At that point the bottles proceed forward on a conveyor leading into the filler.

Also supplied by Kaps-All, the Fills-All Model FA-R Rotary High Speed Pressure Filler is equipped with color-coded tool-less change parts and an advanced touch screen access panel capable of storing up to 150 recipes. Such built-in versatility once again makes this 24-head machine highly suitable for Specialty Blends. Other features include:

• an exclusive stainless-steel dual manifold that eliminates the need for overflow tanks and prevents unwanted spills.

• a station for inserting a dose of liquid nitrogen to drive out oxygen and extend shelf life.

• patented independent adjustable trimming nozzle adjustments that provide 5/1000-in. accuracy.

• closed-tip diving nozzles for optimal foam control and clean filling without splashing.

• Rockwell HMI and controls make it easy to go from one filling task to another quickly by simply picking from a menu.

• User-friendly controls system includes functions like bottle counter, rate meter, and pump-setting controls.

• Stainless steel conveyor extensions can be added to the infeed or discharge side of the conveyor, an option that Specialty Blends took full advantage of. Filled bottles exit the 24-head rotary filler by way of this discharge starwheel.Specialty Blends

Filled bottles exit the 24-head rotary filler by way of this discharge starwheel.Specialty Blends

Adjustable capper

Next in line is a Kaps-All Model C8 eight-spindle capper with an integrated cap elevator. “We like how adjustable the capper is,” says Tindol. “The two pickle potions we fill, 3-oz and 6.3-oz, both take a 28-mm closure. But the Slamzees have a much bigger closure at 64 mm.” The injection-molded PP caps are supplied by Berlin Packaging.

One other feature on the capper that Tindol appreciates is a torque monitor. “We can monitor our torques and if anything is over- or under-torqued it gets blown off the line by an air reject,” he notes. The 8-spindle capper handles both the Slamzees cap that has a 64-mm diameter and the pickle potion caps that have a 28-mm diameter.Specialty Blends

The 8-spindle capper handles both the Slamzees cap that has a 64-mm diameter and the pickle potion caps that have a 28-mm diameter.Specialty Blends

At this point the single-file bottles are more or less randomly spaced, but they get properly spaced by a timing screw just ahead of the shrink sleeve labeler, a Model LX-150 from AFM. The PETG labels, printed flexo in up to seven colors, are perforated by the AFM system just before application. Also from AFM is the Series WSN steam tunnel that shrinks the labels onto the containers. Equipped with multiple steam zones, the tunnel directs the steam heat where needed to produce a precise, finished appearance.

Exiting the steam tunnel the containers pass through air knives from Exair that dry off excess water. Next is an AutoMate AM-DA inspection station. It uses photoeyes to detect a variety of faults including missing cap, crooked cap, down bottle, missing label, and fill level. Should any of these be detected, that container is automatically rejected from the line.

Containers now move through a surge table provided by Kaps-All before arriving single file at the infeed of the Polypack Model TR-I tray former and packer. The machine uses a diverter that splits bottles into lanes: six lanes when filling trays of 18 bottles arranged 6 x 3, or eight lanes when filling trays of 24 bottles arranged 3 x 8. Operators can switch between these formats with a simple press of a button on the HMI screen. The change takes only seconds and does not require any manual adjustments. Shrink sleeve labeler applies PETG labels that are printed flexo in up to seven colors.Specialty Blends

Shrink sleeve labeler applies PETG labels that are printed flexo in up to seven colors.Specialty Blends

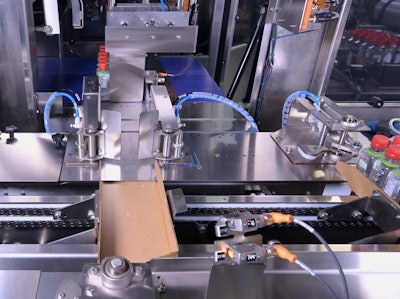

Since Specialty Blends runs three different bottle widths, the lanes also need to be adjusted to fit each bottle width. Polypack created a patented single-point lane adjustment to make this easy, and Specialty Blends represents the first commercial application of it. Instead of adjusting each lane by hand, the operator turns one adjustment wheel. This automatically changes all the lanes to the right width through a linked mechanical system. The design also leaves the option to add servo automation in future models.

Each adjustment wheel includes a SIKO DA095 mechanical position indicator. When it’s time to switch to another bottle width, the operator checks a recipe sheet to find the correct number for that bottle. They turn the wheel until the number on the SIKO display matches the setting shown on the sheet. As the wheel turns, all parts of the lane adjustment system move together to prepare the machine for the new container.

Eliminates change parts

“We will be implementing this on additional machines going forward because it eliminates a number of change parts you need if you are running multiple sizes through our tray packer,” says Chris Harris, division manager at Polypack. “In this case, where Specialty Blends is running three different bottle widths, they would have needed three sets of change parts. Not only does that represent added cost, it means you need space to store the parts and your changeovers are longer because you have to put the new parts in when a new size goes into production. With this single-point lane adjustment system, you turn the wheel to the setting indicated on the SIKO device and you’re ready to go.”

Sensors above each lane ensure that the correct number of bottles, 18 or 24, has accumulated before releasing them onto a staging plate. From there the bottles are pushed at a right angle onto a corrugated tray that has been erected from a flat blank. As soon as the bottles are positioned on the tray, the tray is pushed at a right angle through flap closing and sealing stations equipped with a Nordson adhesive application system. Shown here are shrink-wrapped trays exiting the shrink tunnel.Specialty Blends

Shown here are shrink-wrapped trays exiting the shrink tunnel.Specialty Blends

After sealing, a Videojet ink-jet tray coder prints lot and date codes on each side of each tray. The trays then enter the film curtain of the Polypack shrink bundler, where a heated seal bar closes the film around the tray. The tray continues into a shrink tunnel, where the film tightens around the tray to create a clean, secure bundle ready for shipping.

“One of the challenges we faced is that we don't have very much space here,” says Tindol. “So this line is basically a big horseshoe. In a perfect world, you’d just put everything in a straight line. But we didn’t have that luxury because the space we had available was in a warehouse that we converted for this new line. So that was definitely one of the challenges that line integrator Lakey Packaging helped us solve as we got this line to fit in a tight spot.”