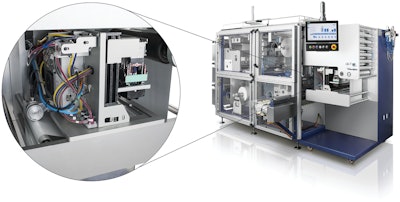

V-Shapes is an innovative supplier of the convenient, hygienic, and sustainable single-dose form/fill/seal packaging machine known as Alpha. At PACK EXPO Las Vegas, the firm debuted its unique AlphaFlex system, which adds inline digital printing to the form, fill, and seal capabilities (1). This compact, professional-grade dosing and delivery system from V-Shapes features high-quality synchronized digital printing on both sides of the sachets. Image #1 in the article text.

Image #1 in the article text.

Notable is that AlphaFlex is powered by Memjet DuraFlex® digital printing technology and ColorGATE, a modular solution for managing color and data throughout the whole package production chain. The V-Shapes AlphaFlex dosing and delivery technology makes it possible for vertical integration of high-volume production of the patented V-Shapes single-dose sachets, eliminating the need to outsource printing and giving complete manufacturing control back to the brand owners and co-packers.

V-Shapes says it was no small challenge to develop synchronized feeds and professional quality printing of the patented single-dose sachets, and the firm adds that the revolutionary filling/converting machine was made possible through a variety of important partnerships, including Memjet, Siemens, and SIHL, as well as the talented V-Shapes engineering team. SIHL is the converter that produces the flexible film materials used to make the sachets. Several different adhesive laminations—some including aluminum foil for barrier purposes and others not—can be used depending on the specific application.

The AlphaFlex features integrated in-line printing into the V-Shapes six-lane ALPHA machine, enabling packaging converters/fillers to accomplish the complete manufacturing process of V-Shapes’ unique single-dose sachets under one roof with a compact footprint and full color branding capabilities—in line, on demand, and with the industry’s highest quality. In the AlphaFlex configuration, the printing module prints a single side of the single-dose sachets inline, synchronized with each other, and precisely married for die cutting, filling, and sealing.

Also new to the portfolio of equipment offered by V-Shapes is its VS dflex near-line digital printing solution. An early adopter of this system is Health Supply US of Mooresville, N.C., which identifies, sources, and delivers safety and medical supplies to frontline workers and first responders. Health Supply US is already operating two V-Shapes Alpha single-dose packaging machines. “Once we installed our first Alpha and were on our way to our second, it also became clear that we could easily do on-site printing with the VS dflex printer rather than outsourcing it,” says Managing Partner Cesar Garcia.

The VS dflex nearline reel-to-reel printer, which also features Memjet DuraFlex® inkjet printing technology, makes it easy to print flexible packaging on site, eliminating the need to outsource printing or to tie up other printing equipment in the plant, especially for shorter runs of customized sachets. For Health Supply US, these acquisitions dramatically transformed the design and approval process for single-dose products, making it easier to meet tight customer delivery deadlines and setting the company apart from the competition.

“I have a printing background, and I looked at all the possibilities of being able to show our clients right away what their packaging would look like instead of putting a file together, sending it to an outside printer, having them print a massive run, and then coming back and putting it on our Alpha for filling,” says Garcia. “By using both the Alpha and the VS dflex, I am able to do everything on site and on demand; and that saves me about 2.5 weeks at a minimum for each project, dramatically improving our cycle time. Now I can go see a client in the morning, and in the afternoon I’m printing out sample sachets for them that I can show them the next day!”

The VS dflex produces full-color printing with aqueous inks at 1600 DPI at a speed of up to 24.7 m/min (90 ft/min). Specialized film from SIHL allows the inks to absorb instantaneously without the need for UV treatment or drying, and the speed at which the dflex runs means it can be used for production runs, not just for samples. The flexibility offered by the combination of the V-Shapes Alpha and the VS dflex has also opened up new opportunities for the firm. Garcia says, “While we were originally looking at packaging sanitizer, we are now also looking at producing various types of creams and lotions. In addition to the need for medical gels that can be conveniently and hygienically dispensed, we also see opportunities for packaging high-end sauces or sampling for cosmetics, as well as products for other industries. It enables us to deliver a complete, end-to-end solution to our clients that goes beyond simply filling the sachets.”

Rovema took advantage of PACK EXPO Las Vegas to launch its CBF (Collect, Buffer, Feed) concept. This unique and patented innovation brings remarkable flexibility to dosing mixed products into a single bag or dosing varied products into their own separate bags in a perforated “chain bag” format—all on a single machine.

The machine demonstrated at PACK EXPO was a Rovema vf/f/s system. Mounted above it was a B&R SuperTrak, which uses magnet technology to guide individually controllable shuttles along a track using long stator linear motors. Mounted at various locations above the SuperTrack were three separate dosing units, each responsible for depositing a different product into containers mounted on the SuperTrak shuttles. When these containers reach the feed tube of the vf/f/s machine, their contents drop down the tube and into a bag formed from a roll of flexible film.

The best way to appreciate what CBF brings to the table is to visualize two typical applications: fastener kits for do-it-yourself furniture and tea packaged in perforated chain bags. Suppose a fastener kit needs to hold a screw, a washer, and a nut. By putting each item in its own dosing unit, all three items can be conveniently dropped into the shuttle-mounted containers traveling around the SuperTrak and subsequently down the feed tube of the vf/f/s system. What better way to make in just one production cycle a single bag holding all three items?

Now picture a marketer of teas who wants to package a three-unit chain bag with green tea in one bag, black tea in another, and chamomile in a third? Once again there would be three dosing units each containing a different tea. When the green tea drops into the feed tube, the heat sealing tools close on that dose and a perforation is made. The same thing happens for the dose of black tea and again for the dose of chamomile. Except that after the chamomile is in, the Rovema tooling cuts the three-count chain bag free and it drops down the discharge chute. Switching from single-bag to chain bag production is done at the HMI panel.

Other examples of applications tailor made for the CBF concept would be a single bag holding a powder and a solid. If the two are dosed from a single dosing unit, it’s difficult to have any real control over the proportion of solid to powder. That problem is squarely addressed when the powder can be precisely dosed from one unit and the solid from another. Or picture a muesli mix. Once again, by dosing oat flakes, raisins, sunflower seeds, and walnut pieces each from their own dosing unit, far greater control of product proportions can be achieved.

Worth noting is that where the chain bags are concerned, the system can be programmed so that each unit is the same size. But should an application call for units to vary in height, this can be programmed at the HMI, too.

As for the kinds of dosing units that can be integrated into the CBF, cup fillers and auger fillers would in almost every case be components made by Rovema. But combination scales can also be part of the mix, in which case Rovema would integrate a machine from another OEM.

Two last observations about the CBF launch. The Janich & Klass PC-based controller governing the Rovema vf/f/s system is tightly synchronized with the SuperTrak’s PC-based B&R controller. And finally, Rovema says the CBF concept can also be applied to its SBS range of machines, which combine form/fill/seal technology with specialized top-shaping systems for compact brick packs and block-bottom bags.

|

One last innovation on the f/f/s side of things was on display at Butler Automatic, a leading producer of web splicing  Image #2 in the article text.

Image #2 in the article text.

As is the case with its previous offerings, plenty of film is accumulated on a system of dancer bars so that while the splice is being made, there is no interruption in the operation of the packaging machine that receives the flexible film. Butler says the S3 is available on new SP1 Automatic Splicers or as a field upgrade on existing SP1 splicers.