After a year or so of hand-applying bar- code labels to the side panels of corrugated cases of private-label vinegars, Nakano Foods was asked by West Coast supermarket chain Albertson's to add bar codes to two adjacent panels of each case. The appeal: Adjacent-panel labeling makes cases easier to read in the warehouse regardless of whether the side or end is showing.

However, applying two labels to each case would have required Nakano to either add another operator or invest in two automatic applicators for each packaging line. Nakano sought to avoid both scenarios by investigating a Model 2140 high-speed wraparound printer/applicator from Weber Marking Systems (Arlington Heights, IL).

"We were really surprised at how well the 2140 applied labels," says Ed Kluss, operations manager, bottling. Nakano purchased two of the corner-wrap labelers-each for a separate packaging line-and installed them at the beginning of this year. The applicator, from Label-Aire (Fullerton, CA), incorporates a Zebra (Vernon Hills, IL) thermal-transfer printer. Weber supplied the entire system to Nakano, developed and set up the software, and integrated the labelers into the packaging lines.

"It's a lot less expensive to go this route versus buying two tamp-blow units for each packaging line," says Kluss. The units are used primarily for Albertson's and a Canadian customer that imports Nakano's Mitsukan branded vinegars.

Starts with software

The private-label vinegar is produced about an hour east of Los Angeles, at Nakano's Rancho Cucamonga, CA, plant. That facility also produces salad dressings and soup bases (see story on p. 54).

On the day of Packaging World's visit, Nakano was bottling its seasoned rice vinegar, which is packed 12 12-oz bottles per case. The labeling starts out in the bottling supervisor's office on a desktop PC that runs Weber's Legitronic labeling software. The software contains a database of all Nakano's labels. It also contains a variety of popular bar-code symbologies, though Nakano currently uses Interleaved 2 of 5.

To start a print job, the supervisor chooses the desired product code from a menu. The software displays the actual label on screen for verification purposes before the print job is downloaded to the printer. "That's a really nice feature," says Kluss. "We've never run into a situation where the wrong label is put on the case, even though we have hundreds of labels." Overall, the software is "really simple, but it's versatile," says Kluss. Setting up a print job is done "all in a matter of seconds," he adds.

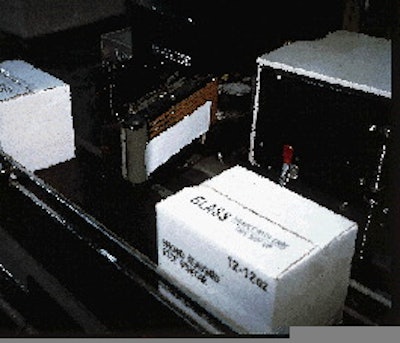

Out in the plant, labeling occurs after cases are top- and bottom-sealed with pressure-sensitive tape. The thermal-transfer printer, enclosed in an industrial housing, prints the bar-code label. The label is automatically peeled from the liner and fed to a vacuum grid labeling arm via stepper-motor-driven carrier belts.

The label waits on the carrier belt until a sensor detects the oncoming case. The labeling arm extends to apply the 3"H x 12"W label to the leading edge of the case, which "collides" with the applicator arm, applying a 6" length of the label to the front of the case. The arm then retracts to follow the contour of the carton and completes the application of the remaining 6" of label to the side with a brush that wipes the label down. A secondary brush that's stationary provides a second wipe down to ensure a solid application.

The printer/applicator provides Nakano with speeds of upwards of 20 cases/min, according to Kluss. "We're exceeding [Weber's] specs," says Kluss. The labelers are rated at 18/min. The high speed is due to the fact that the labelers print the next label while simultaneously applying the current one.

Labeling and ink-jet coding

Although Nakano uses the printer/applicators for bar-code and human-readable text, it continues to print much of the same human- readable text via its low-resolution, large-character ink-jet coders. The reason? The large-character ink-jet printing permits easier reading from a distance, says Kluss, which is helpful to warehouse workers at both Nakano and its customers.

Nakano considered ink-jet coding equipment for the bar code, but in the end felt more comfortable with a thermal-transfer printer/ applicator. "We knew there was high-resolution ink-jet equipment that would cost less, but because we run into so many different types of corrugated surfaces, we weren't convinced that high-resolution non-contact coders would be able to handle that. Print-and-apply is more expensive but we definitely get 99-percent scannability." Printed bar-code labels are verified once each hour with a hand-held unit. "To date, we have not gotten one that we couldn't read," says Kluss.

While Nakano could have purchased the printer and applicator separately and married them together on the packaging line, the company wanted single-source accountability that could be provided by a large vendor like Weber. "We were looking at the service aspect of it. I'm glad we did, because some initial problems we had were quickly taken care of. Their service and support center has been absolutely excellent and fast in response."