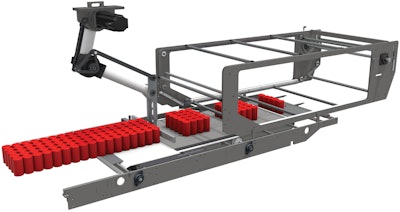

Douglas Machine recently introduced a design improvement in its Contour 60-Series shrink wrap multipacker. A single SCARA robotic arm is now used to meter cans or bottles into the film wrapping section of the machine. It replaces a pair of integrated linear thrusters that were relied on previously, one running in a vertical and the other in a horizontal plane.

“The previous approach was essentially more mechanical in nature in addition to being more complex,” says Steve Lipps, Senior Director of Product Management at Douglas. “A robot provides greater flexibility and range of motion while reducing mechanism complexity. Belts, pulleys, linear slide bearings, linkages, and grease points are reduced or even eliminated. It also addresses workforce issues because there are fewer parts to maintain, fewer changeover points, and an easier cleaning routine.”

Worth noting is that Doughas makes its own robot rather than integrating a robot from an outside source. Lipps says this results in a simpler mechanism optimized for the framework and actuation that’s called for. The essential actuation in this case is a matter of reciprocating back and forth to separate containers from a continuous flow so they can be metered forward in neatly collated groups of 6, 12, or 24 units. The rated speed of the Contour-60 is about 50 cycles/min.

All controls on the Contour-60 are incorporated into the single Logix-based PLC from Rockwell. Lipps says this is another advantage Douglas gains by making its own SCARA robot. “If you integrated a robot from an outside source not only would you have to wrestle with finding the right form factor at the right price, you’d also likely require a separate control system to control the robot independently from the other functions of the machine. It’s so much simpler from a programmability standpoint to incorporate all controls into the single Rockwell controller running the entire machine.” Predictably enough, the other key controls components in the machine—the Panelview HMI, the Kinetix 5700 drives, and the servo motors—are also supplied by Rockwell.

According to Rockwell’s Steve Mulder, Regional Segment Manager–Packaging, this use of a unified machine controller is an approach that’s growing significantly. He also notes that Douglas was among the early adopters in designing machines with a single controller for both traditional machine functions and robotic kinematics.