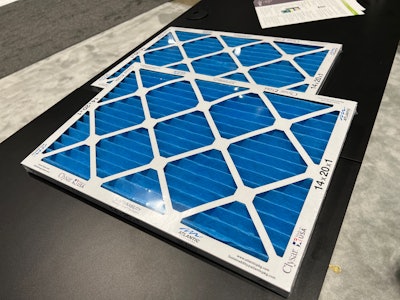

A polyethylene (PE)-based polyolefin film, Clysar's Ultra LEG film is an ideal fit for many markets. But center of the bullseye and demonstrated at PACK EXPO International was an application for furnace filter packages. Furnace filters are so delicate that most non-PVC films would end up bending the filter pack while shrinking in the heat tunnel. But as furnace filter producers seek to eliminate PVC from their lineup for health and sustainability reasons, they still need to maintain a thin, light film that requires only low heat to shrink. The Clysar Ultra LEG film stands out for this application, as well as calendars, school paper, and other product ranges with similar qualities.

"Traditionally, furnace filters have tended to use PVC," says Clysar's Vicki Larson, president. "And the reason why they're in PVC, is because PVC uses a single bubble. It's more of a cast technology. So they can control how much the film shrinks in the machine direction, and in the transverse direction. That's why PVC has been so prominent in the furnace filter industry, because nobody wants this to bend on the shelf.

"But our Clysar technology uses a double bubble. We blow a tube, and then we blow a big bubble. You get equal shrink in both the machine direction and the transverse direction," she continues. "We've been able to develop a film through process and formulation (chemistry rules and technology rocks, right?) That allows us to do this in a true polyolefin. Any other polyolefin would bend this [package, a furnace filter in a primary paperboard carton]. Ours doesn't."