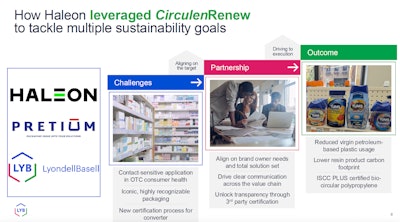

As more brands take a ground-up approach to packaging innovation, they’re looking for solutions that can drive circularity while delivering on climate goals. For global consumer healthcare company Haleon, that meant reevaluating material choices for its iconic antacid brand Tums. Working closely with suppliers across the value chain, Haleon switched to a recyclable bio-based resin for its Tums bottle, aiming to cut carbon emissions without disrupting its performance or appearance, or the consumer experience.

| Read this related article on another package made from bio-based material, in “Win Win Water Debuts 100% Plant-Based, Compostable Bottle” |

Nate McCrary, director, business development at LyondellBasell, shared the details during a session at Packaging World’s 2025 Packaging Recycling Summit that also included project partner Pretium Packaging. The new bottle is made from renewable feedstocks and is fully recyclable in existing infrastructure. “This is a mass-balanced, bio-based material,” he explained, “which means we’re replacing fossil resources with renewable content while maintaining the same quality, consistency, and compatibility with recycling systems.”

LyondellBasell

LyondellBasell

Easing the rollout, the transition didn’t require new tooling or a redesign of the bottle. That compatibility was key, said McCrary, noting that Haleon didn’t want to ask consumers to adjust their behavior. The company also needed to keep manufacturing, labeling, and distribution intact. The bio-based resin helped check those boxes while delivering a carbon footprint reduction of about 70% compared to virgin fossil-based plastic.

McCrary added that this kind of collaboration, between brand owners, material suppliers, and converters, is what makes scalable change possible. “If we’re really going to transition the industry, we have to work together to create solutions that don’t compromise on functionality,” he said. PW