Bower Collective is an e-commerce business that specializes in home care and home cleaning products. Reuse and refill are central to the mission at Bower and the company’s goal to eliminate household plastic waste.

When consumers place an order with Bower, a filled, reusable pouch is mailed to them. Upon receipt, they empty the product into their durable home spray bottle (or other container appropriate to the cleaning product) and then flat pack the pouches and pop them into a prepaid mailer to send them back to Bower to be cleaned and refilled for the next customer.

The system uses the concept of a unique digital passport tracking system, which Bower says it developed in collaboration with Reath. “Each pouch has a unique digital ID, so we know exactly which batch of product is in each pouch at any given moment in time,” says the company.

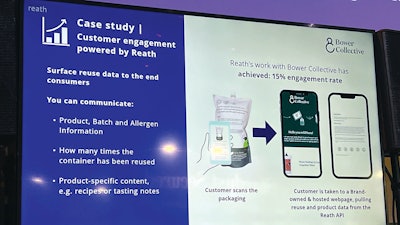

Reath co-founder Emily Rogers spoke at the AIPIA (Smart Packaging Association) World Congress in November, and explained to attendees how this works. Reath first tags the reusable packaging. Tags like NFC, RFID, or traditional barcode are available depending on the package and application, but Bower uses QR codes, which are serialized and digitally printed onto the pouches themselves. The QR codes are scanned on the automated filling line, at speed, to input information on the product batch that has gone into each specific pouch.

The QR code serves two masters. On the consumer side, provenance information and directions foster consumer engagement once they’ve scanned the QR with a smartphone. For Bower, logistics and performance information is gleaned at each scan, both on the filling lines and upon collection as the empty pouches are mailed back.

“We’re able to use the data we’re collecting on the reverse logistics and the filling times to improve the reuse system to be more commercially competitive with single-use product,” Rogers says.

It also helps Bower to track the reuse cycles, so the consumer can scan the QR code and find out how many times the pack has been used, how much plastic waste has been saved, and how much carbon has been saved, too.

“So, they’re giving the packaging a bit of a story and history,” Rogers added at the World Congress. “Plus, they include service information on how a consumer should actually use the product. The QR can also communicate batch, product, and allergen information to the consumer. We have about a 15% engagement rate with reading the QR codes on the packaging. And all this [consumer-facing information] is hosted on a brand-owned webpage, and no app is needed to access it. They just scan the QR code, and it takes them to the information.”

An interesting sidenote on Bower’s packaging system: When it was first launched, Bower was taking used pouches and washing them, inside and out, for reuse. The company soon realized that this process was neither environmentally nor economically scalable. So, Bower sought to design away the need to wash the pouch interior and still deliver products safely. The company arrived at what it calls the BowerPack, which uses the digital passport system. They’ve designed a one-way valve system in the spout that ensures once a consumer has emptied the product into durable dispensers at home, no air or contaminants can get back into the pouch, eliminating the need to clean the inside of the pouch. The consumer simply screws the cap back on and returns the pouch to Bower for quality control and refill.

“The experience of using the pouch is also improved, as there’s less potential for mess and spillage, and we have a beautiful, digitally printed pack that we can use again and again. At the end of the pouch’s usable life, we aggregate for recycling with our specialist U.K. partner,” Bower says on its website.

The company started with a limited-edition, 750-mL trial run of the BowerPack across two of its product lines—Grapefruit Washing Up Liquid and Lavender Laundry Liquid—with the goal to roll out BowerPack across its entire refill range. PW