Based in Germany, natural cosmetics manufacturer biana GmbH & Co. KG is all about “nature to the core,” says CEO Nicki Gregor Streit. That’s why, last year, it switched from a standard polyethylene tube for its skincare creams to one made from processed spruce and sugarcane.

“From our point of view, the development toward a sustainable company is an urgent necessity, and we want to take a pioneering role in the cosmetics world,” says Streit. “Essential for the complete biana range is the particularly high-quality, cold-pressed grape seed oil. Of course, a sustainable orientation also includes a sustainable tube.”

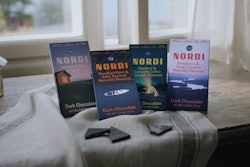

biana’s product range, which includes a 50-mL hand cream, a 75-mL day cream, a 75-mL night cream, and a 100-mL body lotion, were introduced in August 2018 in an inverted PE tube. In October of that year, the company began searching for packaging that would offer the highest amount of sustainable and organic resources. The PICEA™ wood tube from Neopac met that criteria.

The PICEA tube is made from 95% wood flour content, originating from industrial sawing waste, and bioethanol from sugarcane, and 5% plastic additives and color pigment. Due to its renewable content, the package has a 40% lower carbon footprint than a conventional PE tube, while offering the same barrier properties, decoration options, rigidity, and recyclability as a conventional tube made from 50% high-density PE and 50% low-density PE.

According to Neopac Head of Materials Science & Development Dr. Philippe Kern, Neopac selected a sugarcane-based bioplastic for PICEA “due to its excellent carbon footprint and good technical properties for tube manufacturing.” Neopac produces the tube body via coextrusion and compression-molds the shoulder onto the body. This is done at its facility in Debrecen, Hungary, where it also offset-prints the package.

Despite the tube’s fine, wood-grain surface, Dr. Kern says it can still be decorated via traditional offset and screen-printing processes, although the rougher surface needs to be considered in artwork design.

According to Nóra Mónus, Sales Manager Cosmetics, for Neopac, the tube’s matte finish and wood feel were one of the aspects of the PICEA tube that appealed to biana because it “matches the product perfectly.”

The biana line of four skin cream products debuted in the new PICEA tube in November 2018 in German pharmacies, where it is sold exclusively.