Surveying the three precision packaging lines at authentic Greek style-yogurt company FAGE USA Dairy Industry, Inc. (pronounced fa-yeh), Bernard McConaghy remarks, “In terms of yogurt plants, this is as good as it gets.” McConaghy is the production manager for FAGE USA, the U.S. operations of FAGE Dairy Industry S.A. of Greece, which opened its 120,000-sq-ft state-of-the-art U.S. facility in Johnstown, NY, in April 2008.

Operating two shifts daily, five to six days a week, the $125 million facility produces more than 16,000 tons of “ridiculously thick” strained Greek yogurt each year and is in the process of expanding its packaging capabilities to keep pace with growing U.S. demand for the product.

Says McConaghy, “When you look at FAGE Total yogurt, it looks significantly different than a common, store-bought yogurt. It tastes and feels different. I think that this distinctness adds to its allure in this country.”

Also distinct is the brand’s crisp, white packaging, which includes rounded plastic cups and tubs in a range of sizes, as well as segmented “split cups” for flavored yogurt varieties. To fill the varied pack sizes and configurations at the desired speed and to the greatest hygienic standards, FAGE USA uses three aseptic filling lines from Oystar .

“These machine are world-class,” says McConaghy. “They are top-of-the-line filling machines in terms of capability and reliability.”

Product quality enhanced by packaging

FAGE Total yogurt is produced by a proprietary process that results in a thick texture and a creamy taste. The brand is sold in 0%-, 2%-, and 10%-cream versions in sizes from 5.3-oz cups to 35.3-oz tubs. The 5.3-oz size is offered in five flavors—honey, peach, strawberry, cherry, and blueberry—in a unique, two-compartment cup that keeps a serving of plain yogurt separate from the flavorings.

An import from Greece, the “split cup,” as it’s called by FAGE USA, “allows the consumer to bend over the side cup [of flavorings] and pour them directly onto the yogurt or eat the flavorings with the yogurt in the desired amount, rather than having them premixed,” explains McConaghy.

Both split cups and round cups are made from polypropylene and are supplied by Berry Plastics and Polytainers, respectively.

When FAGE USA began operations two years ago, its packaging capabilities included the Oystar Gasti 82P aseptic filling machine, for 5.3-oz split cups and 6- and 7-oz round cups, and the Gasti 43P, for larger, 17.6- and 35.3-oz tubs. In June 2008, the company added a third machine—the Hamba FL 8/8 CA, from Oystar Hamba—to keep up with growing demand for the yogurt.

Of the three machines, McConaghy notes that “the Hamba is faster, it is mechanically easier to maintain, and its design is arguably the most elegant.” He adds that in selecting the machine, FAGE USA was looking for speed, reliability, and availability.

“The machine requires almost no annual maintenance because of the design. It’s a servo motor-driven design,” he says, “which means that it’s not designed mechanically to be interlocked from the beginning of the machine to the end. If you have a problem with the machine, you can isolate it and quickly fix it without having to disrupt the other mechanical portions of the machine.”

Like the Gasti machines, the Hamba is an aseptic filler, designed so that filling and sealing take place in a totally enclosed, hygienic environment with sterilized packaging materials. Says McConaghy, “The aseptic feature of the machine is really conducive to sustaining the quality of our yogurt.”

Machine masters eight cups at a time

Filling operations on the Hamba take place at a rapid 544-cup/min speed—nearly twice the pace of the 280-cup/min 82P machine. On the day of Packaging World’s visit to the plant, FAGE USA was running a split-cup package on the line, filling a 5.3-oz size of FAGE Total Classic Yogurt with Honey (see related video at packworld.com/video-29529).

The packaging process begins when one of the three Hamba operators on the line manually loads the machine with stacks of preprinted PP cups in rows of eight. Each stack then releases one cup into a slotted conveyor below, forming a row of eight cups that are then conveyed into the cup decontamination station of the machine. There, the cups are dosed with a mixture of hot, sterile air and hydrogen peroxide, after which they are dried at a temperature of 400°C.

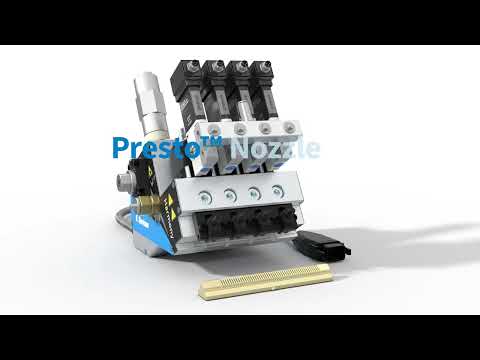

The row of cups leaving the cup decontamination station is then conveyed underneath the machine’s filling nozzles; 16 cups are filled in one cycle. The yogurt reaches the nozzles after being pumped from a storage tank upstream, through a feed line and into a filling hopper. At this stage, the yogurt is still warm from processing and is dispensed into the cups at a temperature of approximately 100ºF. For fruit and honey varieties, flavorings are pumped in a similar manner into a separate hopper and are filled into the double-compartment cup first, before the yogurt is added.

As McConaghy explains, the Hamba machine is run by a local PLC from Allen-Bradley that communicates with the process PLC to regulate “product collection, cup dispensing, yogurt flow—the whole operation of the machine.”

After filling, round cups of plain yogurt advance to a station where a piece of parchment paper is dispensed on top of the yogurt to absorb excess whey from the product after settling. When split cups are being run on the line, this station is inactive.

At the next station, an aluminum lid is placed on top of each cup and is sealed to the rim of the cup using a heated sealing element. Leak detection follows, during which another heating element heats the air beneath the lid in the yogurt. As the air heats up, it expands, deflecting the lid. Those cups that do not deflect at a certain minimum distance are considered “untight.” After detection, the cups are conveyed to the next station where those packages without leaks are ink-jet-printed with the expiration date, the machine-designated letter, and the production time by a Videojet Excel 2000 dual-head ink-jet printer that traverses across two rows of eight cups at a time. Faulty cups do not get a lot code.

Following printing, cups in batches of 48 are lifted by a robotic gripper arm and placed into four awaiting corrugated trays (12 cups/tray), which are then conveyed out of the machine. The Hamba receives the erected and glued trays from a conveyor that leads to an adjoining room that houses the end-of-line equipment. The tray erector is a Tecma Pack machine, model FM 3000 B, equipped with a Nordson ProBlue 7 adhesive dispensing system. The tray erector, as well as other end-of-line machines, were integrated by Aries Packaging.

Completely automated end of line

Once the tray-packed cups leave the Hamba machine, they are carried by conveyor into the room next door through an opening in a glass partition. Here, they undergo x-ray inspection by a Smiths Heimann Eagle Pack 430 x-ray detector from Smiths Detection that checks for weight control and for the presence of metal, stainless-steel, glass, or plastic. Trays containing defective product are diverted from the line.

Acceptable product is conveyed into an ARILID hooding machine from Aries Packaging. Before the corrugated hoods have been placed on top of the trays and glued, they receive a label on the two shorter sides, with the lot expiration date, product SKU, time of manufacture, and the machine on which the product was manufactured. Both labels are printed and applied using Markem-Imaje model 2420 label printers. The labeled hoods are then attached to the trays, which are collated in a 2X4 stacked-case group and moved vertically out of the top of the machine to an overhead conveyor for palletizing.

The two groups of four cases of finished product are picked from the conveyor by an ABB IRB 660 robot from ABB Robotics and placed on a pallet below. After each layer is formed, a second ABB robot places a corrugated interlayer on top. When the pallet load is complete, it is automatically carried out of the palletizing cell on roller conveyors. After exiting the cell, the pallet is moved via a system of automated shuttles and roller conveyors into a cooling tunnel, which gradually cools down the product from its processing temperature to its storage temperature of 36°F to 38°F.

Keeping up with consumption

McConaghy emphasizes that speed and uptime were critical considerations for the selection of the Hamba line. Running three cup sizes ranging from 5.3 oz to 7 oz, the Hamba had to provide flexibility and ease of changeover. He explains that the slotted conveyor that carries cups through the machine has been designed to accommodate all three sizes and both split and round cup designs. “The most complicated changeover takes about an hour,” he relates. “A routine changeover from one food product to another takes just 20 to 30 minutes.”

Reflecting on the process of installing and commissioning the Hamba equipment, McConaghy concludes: “Attention to detail is extremely important. The more attention to detail that you invest, the sooner you will be able to gain the benefits of the machine’s capabilities. And, the sooner you get the machine operational, the sooner you can focus on upgrading its efficiency to really help sustain the benefit that you added the machine for.”

FAGE USA has plans to further expand its packaging capabilities. In May, it will add a fourth aseptic filling line for its larger cup sizes that will double the speed of its Gasti 43P.