The consumer packaged goods (CPG) industry faces a bit of a manufacturing mess at the moment as a result of mega trends that are forcing these companies to upgrade operations. From consumer buying behavior that is ever-changing, to cybersecurity threats, sustainability initiatives, supply chain disruptions, and a skills shortage that portends problems on the plant floor, CPGs are at the point where they have to do something different.

Given the shifting sands upon which CPGs currently conduct business, there is an innate understanding within the industry that they must update antiquated equipment and processes. And the necessary next step for them is a digital transformation. Unfortunately, it doesn’t seem to be happening.

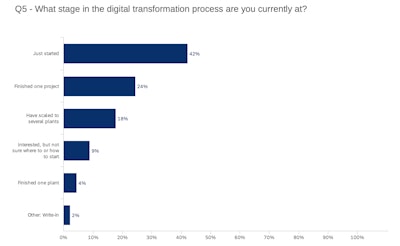

In a survey conducted in May of 2023 by PMMI Media Group, of the 166 CPG respondents, 66% have not started a factory floor digital transformation. And, of the 34% that have started, 42% have only just begun, and 24% have finished just one project. A mere 18% are at a stage where they have scaled digital transformation across several plants.

The respondents range from small breweries to large food conglomerates with a solid assortment of titles, including CEO, vice president of global engineering, continuous improvement manager, controls engineer, and more. Most say that they are following an executive mandate to digitize the plant floor, as many (57%) acknowledge the people making the strategic digital transformation decisions are at the C-suite or VP level. Yet, despite these marching orders, most (59%) don’t have a specific person in charge of digital transformation at the project level.