This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

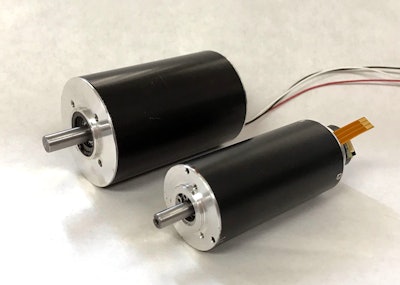

These motors represent a technical leap over existing DC brushless motor technology:

• Flux density over 10,000 Gauss - achieved by using Halbach magnet designs (like those used in Particle Accelerators)

• SMAC’s patent pending PRINTED COIL technology - uses circuit board manufacturing methods to make coils with the following advantages;

• Very low cost tool up

• Very quiet because of the near perfect coil layer location

• Nearly zero variance in resistance

• Allows the combination of coil/encoder reader head/ controller amplifier all in the same circuit board. (Eliminates wires, soldering, etc.)

Torques are 2X that of conventional designs. SMAC also is making special motors for OEM proprietary application - like the HT 100 designed to integrate into a specific customer’s filler line.

SMAC HT motors have much higher torques than the current market leaders and are priced very competitively. Design possibilities exist to reduce motor foot print/weight and even sometimes eliminate a gear.

SMAC’s built-in feedback system gives SMAC’s devices the unique mechatronic ability to “perform a task and verify its quality at the same time.” This would allow the actuators to quality check key processes 100% in real time and feedback the results.