This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

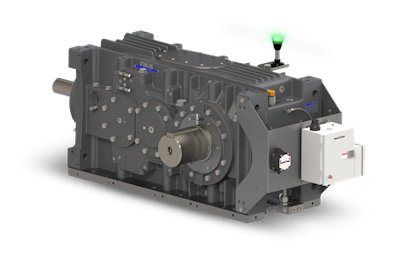

Customers can now choose from four levels of monitoring, from continuous monitoring of overall gear drive vibration and temperature, all the way up to comprehensive cloud-based notification of abnormalities. And in an industry first, the base model now comes standard on select new Falk V-Class and A-Plus Gear Drives.

The four models are:

• Model 1010: Detect abnormalities in overall vibration and temperature.

• Model 1020: Oil condition monitoring, using alerts to make oil changes only when necessary.

• Model 1050: Comprehensive monitoring and reporting, including vibration diagnostics, operating speed, and motor current.

• Model 1150: Connect to the Rexnord cloud-based portal for anytime/anywhere access to insights into asset condition, valuable analytics, and email alerts at enterprise scale.

All four offerings communicate gearbox condition status via included Andon light and an industrial communications card supporting EtherNet/IP®, Modbus® TCP/IP and PROFINET® standards. A message display is also available as an option.

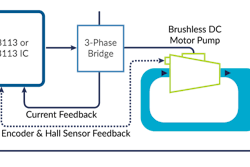

Rexnord’s Smart Condition Monitoring System uses proprietary algorithms to continuously compare sensor data against models of healthy gear drive operating conditions. Abnormal conditions trigger alerts to onsite visual indicators, the control system, and at the highest level, the Rexnord Connect Portal.

The system puts data in context, enabling customers to focus on outcomes; teams know what action to take when and why. Manufacturers gain the ability to replace time-consuming, hands-on equipment inspections with digital technology that enhances team safety, extends asset life, and lowers inventory and operating costs.

The Series 1000 Smart Condition Monitoring System offers rich features and functions to help manufacturers avoid unplanned downtime and eliminate unnecessary maintenance costs. Installation is fast and easy. Existing Falk Gear Drives can be upgraded with models 1010,1020,1050, and 1150 at a certified repair facility or your own facility, by certified Rexnord third-party technicians or by your qualified personnel with assistance from Rexnord or third-party technicians.

"This more cohesive, cost-effective approach eliminates unnecessary maintenance activities and significantly lowers total cost of ownership for mission-critical and standard gearbox assets,” says Rick Morse, Rexnord vice president of innovation & digital solutions. “The new models accelerate the customer’s journey from run-to-failure or schedule-based maintenance to condition-based maintenance.”