This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Users benefit from reduced reaction times and higher productivity, as well as easier maintenance repair of their plant and machinery.

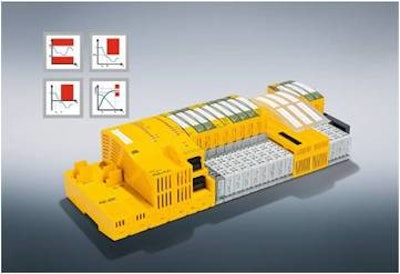

High productivity in manufacturing is closely linked with safe speed and motion monitoring. Pilz now has a new I/O module for the control systems PSSuniversal PLC and PSSuniversal multi from the automation system PSS 4000, designed for safe motion monitoring of machines and distributed plants.

Safe motion monitoring with one rotary encoder

It enables safety functions for speed monitoring in accordance with EN 61800-5-2 with only one Sin/Cosrotary encoder, or in a combination of rotary encoder and proximity switch with additional gear monitoring. The use of just one rotary encoder minimizes the installation work. As the module can be connected to all common rotary encoder/feedback systems (sin/cos, TTL, HTL, proximity switches), existing encoder systems can continue to be used. The new module has local fast shutdown of drives, irrespective of the PLC cycle time. As a result, the reaction time is reduced and plant productivity increased. Up to 8 axes per controller can be monitored up to Performance Level (PL) d. As a result, the motion monitoring solution with PSS 4000 is particularly suitable for larger applications.

Ease of handling

The safe monitoring function is fully integrated within the user software. As a result, users can set up the speed functions via the software tool. Projects can be implemented quickly and can be easily adapted. It is even possible to change threshold values during operation, for example.

With the new encoder module and corresponding software blocks it is possible to implement the safety functions SSM "Safe Speed Monitoring", SSR "Safe Speed Range", SDI "Safe Direction" and SOS "Safe Operating Stop".

For more information on the automation system PSS 4000, please click here.