This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

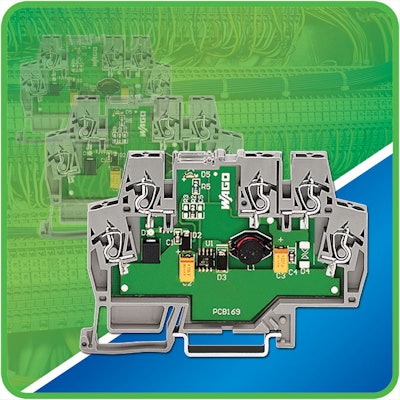

Traditionally, driving low-current circuits, e.g., analog transducers at 10 V, within a control panel requires an extra 110 V power supply. The 859 Series DC/DC Converters eliminate redundant power supplies for 5–12 V applications, including running 24 VDC sensors and other controls on battery power.

The touch-safe, 859 Series DC/DC Converters may also trim safety-related expenses. Engineering Services manager, Carey Perschke, explains that costs increase exponentially when isolating control panel segments for low-voltage circuits.

“Power supplies require safety-related items such as touchguards and requisite labeling,” Perschke says. “The DC/DC converters enable the input/output to reside in the panel’s low-voltage portion. Snap them on DIN-rail like terminal blocks — no extra protective measures required.”

All 859 Series DC/DC Converters feature short-circuit protected outputs, reverse voltage protection (input) and TVS diode protection. Line regulation from 0.5% to 2% (varies per model) ensures power consistency. Efficiency up to 85% limits heat generation and power draw. Manufactured at WAGO’s Germantown, headquarters, select units carry UL 508. Models: 24 V/ 5 V (0.5A DC), 24 V/10 V (0.5A DC), 12 V/24 V (0.25A DC) and 24 V/12 V (0.5A DC). Contact factory for custom voltage ranges.