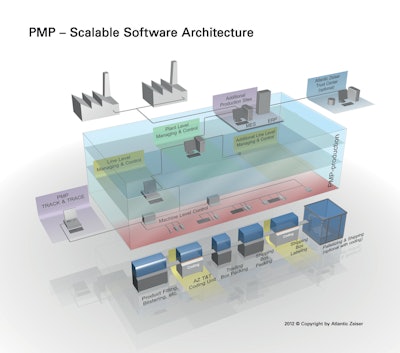

Using interfaces to access the relevant data on all levels of a production system it makes them available as required in real-time during the individual process stages. PMP can be embedded into adjacent and higher-level software systems such as MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning), or even used as an MES itself.

In addition to the universal control of different production levels, PMP Track & Trace also offers individual reports and audit functions as well as an integrated random number generator for unique product ID codes.

PMP production controls the processes across different levels within a production system. Today, modern production systems are divided into the machine level, line level, and factory level in terms of software. Above this is what is known as the ERP/MES level. Modules for generating and managing unique code numbers based on random numbers are housed within a scalable software architecture.