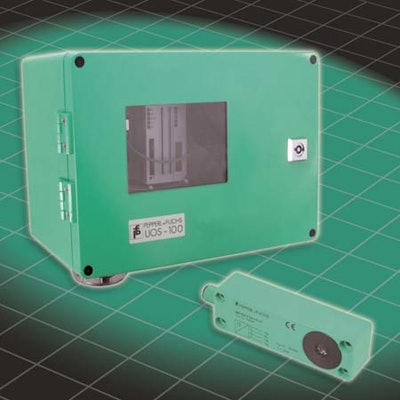

Designed to enhance error proofing in demanding industrial assembly applications or to allocate objects in assembly line production and other quality assurance systems. System removes tool motion limits previously incurred through “footprinting,” resulting in higher productivity without loss of process control. UOS-100 is a complete system, from propagation time measurement to the output of the calculated x, y, z coordinates of the object to be positioned. Control interface monitors and controls as many as 4 workstations at the same time.

Phone: 330/486-0001

www.am.pepperl-fuchs.com