What would happen if package designers collaborated with packaging engineers on new package designs to make sure equipment was in place when needed to run the new packages most efficiently? The world would be a better place. That is the premise of a paper being presented at this year’s Flexible Packaging conference in Orlando (http://www.4spe.org/conf/flexpack05/) by packaging automation supplier ELAU Inc.

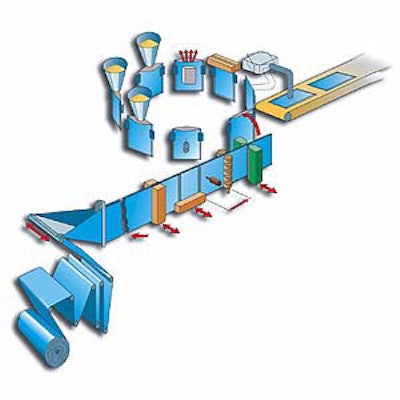

Today’s mechatronic packaging machines are much more flexible than the last generation according to the author ELAU’s John Kowal. Take these capabilities into consideration in your next package design project he asserts and designers will maximize their competitive advantage in terms of package attributes and operational efficiencies.

The presentation gives several examples of capabilities and applications on the market today many the result of European technology to give designers useful ideas about machinery functionalities to discuss with their company’s packaging engineers.

Kowal says he got the idea for the paper from a Kraft Foods packaging engineer he met at the 2004 Flexible Packaging Conference who attended to learn more about materials so he could be more effective in his job.

The goal of this session is not to turn designers into a packaging or project engineers according to the paper. It’s also not to judge whether to design a package to fit within the constraints of some existing machinery or whether to specify machinery capable of running an innovative package. Those considerations will result from the packager’s strategy says Kowal because cost-reducing the package and adding cost to achieve marketing value are both of course valid strategies.

The intention is to give designers information to help them collaborate more effectively up front with the people who will be running their new package design. The result will be a strong business case that will compete effectively against other capital project proposals that may have nothing to do with packaging at all.

John Kowal is the global marketing manager for ELAU Inc. based in Schaumburg Illinois. ELAU is the world’s largest supplier of automation systems for servo packaging machinery equipping over $1 billion worth of machinery each year. Kowal is an active member of the Institute of Packaging Professionals of which ELAU is a Benefactor. He is also active in the OMAC Packaging Workgroup World Batch Forum (ELAU is a WBF Sponsor) these two groups’ Make2Pack joint working group as well as a member of ISA ISPE and BMA.

Contact ELAU at [email protected] or visit www.elau.com.