Filling machines with linear process sequences tend to be more efficient, easier to use, and easier to maintain than rotary filling systems. But filling speeds on linear filling systems are often limited by attempts to minimize the machine footprint. So when a Brazilian cosmetics maker asked groninger & Co. for a liquid filling system flexible enough to handle multiple bottle formats at 150/min while still occupying a minimum footprint, the German machine builder came up with an innovative design based on the eXtended Transport System (XTS) from Beckhoff.

The fundamental requirements for speed, flexibility, and minimal footprint made it impossible to implement the machine layout that groninger originally envisioned: a monoblock system consisting of a volumetric filling machine and a continuous-motion capper. The high output that the customer was seeking would have required extensive accumulating conveyors between filling and capping stations, and there was no space available for that. By opting for XTS instead, groninger was able to design a highly compact bottle-transport unit between the system’s filling and capping stations. “By eliminating the accumulation conveyors,” says groninger’s Otto Helmle, Sales Director, “we were able to reduce the system length from 7.5 meters (24.60 ft), as originally estimated, to approximately 6 meters (19.68 ft). It’s a linear system that still meets the output requirements of the Brazilian customer. Using conventional methods and approaches, this would only have been possible with a rotary filling system.”

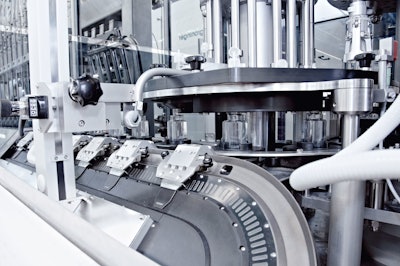

The XTS system in this line consists of a total of 20 straight motor modules, each 25 cm (9.84 in.) long, and semicircles used as curve modules. The result is an oval track with a length of approximately 3 m (9.8 ft) having a path velocity of 1.5 m/s (4.92 ft/s) and a maximum mover acceleration of 10 m/s2 . The mechatronic system uses 30 movers, each fitted with a semi-circular gripper. These grippers attach to pucks that hold the filled bottles. The whole system is controlled by a single Beckhoff C6920 Industrial PC, which is capable of very fast, deterministic control.

The 30 movers operate along the oval-shaped track in three groups of 10. First, a group in the filling area grabs 10 bottles in pucks that have just been filled and transports them forward until they reach the rotary infeed turret of the capping station. There the bottles in their pucks are transferred onto the platforms that take them through the capping process. Once the pucks are out of the XTS movers, that group of 10 movers travels back along the bottom portion of the oval-shaped track to begin the cycle again.