Safely handling a wide range of functions in the overall filling process, packaging machines from groninger include container washing/sterilizing and syringe completion as well as capping and labeling. Lately the firm has focused on the contract packaging market by introducing the groninger lite-F, designed to offer affordability with high-quality automation primarily in applications where aseptic filling is not required.

“With the lite-F, a contract packager who must run 10 different product types in one shift, for example, no longer needs a significant equipment investment in order to maintain their required throughput,” says Dave Gozlan, Business Development Manager at the Charlotte, NC-based firm. Not only does the lite-F ensure ease of operation through quick, tool-less changeovers, it also offers comprehensive machine state reporting and monitoring along with production planning integration.

Also making this machine a first is that it’s manufactured at groninger USA’s Charlotte, NC, facility as opposed to being made in Germany where the parent company is headquartered.

As the cross functional team of groninger specialists began in-depth analysis into what kind of control system to implement, they gravitated toward a PC-based control solution from Beckhoff Automation. “Technology standardization and cost control were the key deciding factors in the move to Beckhoff PC-based control, enabling groninger to provide customers a high-quality machine at a lower price point along with a logical migration path,” says Gozlan. Development progressed quickly, moving from design to machine production in under a year.

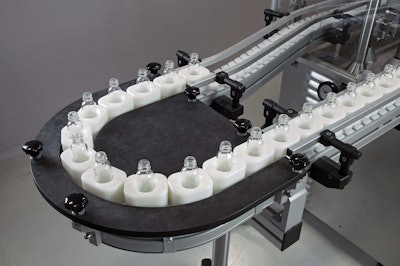

The transfer system on the lite-F machine is designed as a conveyor loop with varied operation for puck and puckless transport, with an alternating gate that can be adjusted to suit a wide range of container sizes. groninger customers can use pucks for smaller containers, and large containers can be conveyed with or without the transport puck. The lite-F can transport two objects at a time, handle double-filling, and easily adjust the fill volume in each bottle. The filling system on the lite-F utilizes well-proven groninger positive displacement pumps, yielding high accuracy. The seal-less and gasket-less rotation piston pump format has been a competitive selling point on all groninger machines for many years.

Intel inside

The entire lite-F machine is fully automated by one CX5020 Embedded PC from Beckhoff, which is equipped with an Intel® Atom™ Z530 processor (1.6 GHz). The multitasking CX5020 runs TwinCAT 3 automation software that handles all facets of control for groninger—including the engineering environment for programming and the controller runtime. “I especially appreciate the customer-friendly licensing structure in TwinCAT 3, as well as the ability to program in the engineering environment for free,” says Stefan Winzinger, Electrical and Automation Engineer at groninger. The CX5020 on the lite-F also runs Windows Embedded Standard as the operating system so groninger can easily include user manuals in PDF format, video tutorials for machine operation and troubleshooting, provide access to Web pages, and set up standard connected devices such as printers.

“The CX5020 represents the perfect mix of price and functionality with ample processing power for the current lite-F machine, and it can accommodate future upgrades,” Winzinger adds. “With an Embedded PC, we are able to run the PLC, HMI software, safety, and the motion controller all on the same centralized hardware device, eliminating the need for many expensive hardware components. This is all done in a compact DIN rail-mounted format that reduces machine footprint and the size of groninger electrical cabinets.”

The lite-F machine is enriched with a wide range of multimedia reference materials for customers, including video tutorials for faster setup, “advanced” demonstrations to master more difficult tasks, and troubleshooting assistance directly through the HMI. Through the PC-based control platform, groninger also has the ability to introduce Internet-based services to customers including remote connectivity via a “VPN tunnel” connecting the lite-F to groninger support in North Carolina. Access is gained through a remote video system (RVS) using an included webcam that can be set up quickly when needed. When a customer logs in, the groninger support team can take control of the camera (tilt, swivel, zoom) and get a clear picture of support needs to provide immediate troubleshooting assistance. Another use case for the webcam is for groninger to walk customers through new operations, such as filling new and unusual bottle types.

For visualization, the CX5020 Embedded PCs run the HMI software programmed using the COPA-DATA platform and are connected to Beckhoff CP3912 12” multi-touch Control Panels. Some multi-touch functions, such as zooming, drag and drop, and scrolling up and down, are used when viewing web pages, PDFs, and other documentation via the CP3912 display. The Control Panels on the lite-F were designed with Beckhoff to feature a five-button extension, including emergency stop on the front of the panel. These built-in mechanical buttons eliminate the need for groninger to manage the intensive labor required to wire their own connectors and install accessories into the panel.

Style and quality

“While we’ve designed an incredibly cost-effective machine, the elegantly-designed CP3912 adds a significant degree of style and quality. In addition to the savings from the built-in mechanical buttons, the overall plug-and-play design with DVI/USB extended connectivity was also a welcome benefit,” Winzinger explains. “Installing the CP39xx series on the machine takes approximately 10 minutes compared to two days required to build an operator panel box and wire it up. This drastically reduces cost in machine assembly and gives us a much more sophisticated look when compared to the large, boxy displays that are still all-too common in many other machines offered in the packaging field.”

Further, industrial Ethernet technology also helped streamlined the lite-F controls architecture. “The EtherCAT system from Beckhoff helps us implement new customer requirements seamlessly and effortlessly. In the future, should we require any kind of additional communication interfaces, there are Beckhoff hardware and software gateways for that,” Winzinger says.

Combining all system communication onto one bus, EtherCAT I/O is implemented throughout the lite-F machine with both IP 20 and IP 67 protection formats. “The machine-mountable EtherCAT Box modules in IP 67 save space and cabling, as they can be installed much closer to field devices,” Winzinger adds. “This results in significant time and installation savings, as connections are made using standard cables with M8 connectors.”

Another EtherCAT I/O solution, a Beckhoff TwinSAFE system controls all safety functionality, including the e-stop on the operator panel and guard doors on the machine. It also safely switches off power to all drives in an unsafe situation and can power off pneumatic equipment during an e-stop event or if guard doors open. “The integrated safety provided by TwinSAFE eliminates the need for a separate, stand-alone safety system and the associated wiring, enhancing cost and space savings,” Winzinger says.

The lite-F machine has racked up considerable results shortly after its introduction at the beginning of 2015. “Through the PC-based control platform and a standardized I/O system with integrated safety, groninger has achieved approximately 23 percent savings in equipment cost and over 50 percent reduction in machine footprint,” Winzinger reports. “This is especially important because the ambitious footprint goal for the lite-F was a machine design that could fit through a regular doorway without any disassembly. This adds incredible appeal for cost-conscious contract packers and small start-up manufacturers with limited plant floor space and infrastructure.”

“The PC-based platform from Beckhoff will carry over into other machines we’re developing and manufacturing here in Charlotte,” adds Gozlan.”The cost-effective software and hardware we use is also quite scalable and can be easily implemented into other machines for any liquid filling application.”