By replacing a pneumatically-driven actuator with a screw-driven linear slide governed by a servo motor, Omega Design made its Classic SL-18 shrink bundler more appealing to the ever-increasing number of customers who perform changeovers frequently.

The actuation in this case is the one that pushes collated containers into the shrink film. According to Devendra Shendge, a product development specialist at Omega Design, pneumatic actuation allowed excess play and uneven motion control, resulting in increased set-up time and maintenance. More important, the inconsistent movement of containers through the pusher area led to misalignment and jams, especially where frequent changes in package size or shape is the order of the day.

“We needed an intelligent yet cost-effective solution that could handle a variety of packages,” says Shendge. “Besides, air can be expensive, and the pneumatically-driven actuator used quite a lot.”

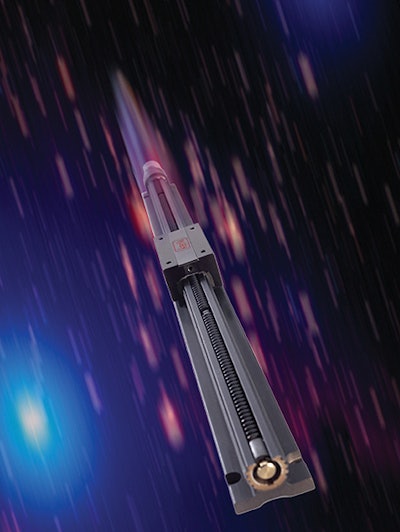

The solution for Omega Design was reached with help from Kerk Motion Products. The pusher station is now actuated by a Kerk RGS™ 10000, a new screw-driven linear slide noted for speed, accurate positioning, and long life in a compact assembly. Omega Design engineers worked with Kerk to couple the RGS 10000 with an Animatics servo motor in an intelligent-motion solution. The servo motor turns the linear slide’s screw, and the carriage attached to the screw actuates the pusher.

The linear slide, which is driven by a precision-rolled stainless steel lead screw, is governed by a servo motor, whose integrated drive is governed by the machine’s PLC. The net result is that the pusher station now has an intelligent actuator.

“Now we can accelerate or decelerate the pushing action,” says Shendge. “This is critical when dealing with multiple package shapes and sizes. If you just thrust them through the machine at top speed, you can damage the packages and the machine.”

An added benefit brought by the new actuator is that the machine can now be programmed to adjust to various product sizes and shapes through recipe-driven settings specific to each package’s handling needs. “Plus,” adds Shendge, “we can take the feedback from the servo-based system and use that data to improve the overall efficiency of the machine.”

The RGS 10000 is the largest screw-driven linear slide made by Kerk, and Omega Design was the first to put one in a packaging machine. “At Pack Expo International in Chicago last November, we exhibited the Classic SL-18 bundler with the intelligent pusher in it,” says Shendge. A maker of personal care products saw the machine at the show and liked the Kerk linear slide so much he asked Omega to incorporate it instead of a pneumatic actuator in a machine he had already been quoted.

“The new machine with the RGS 10000 should be installed in the next few months,” says Shendge.