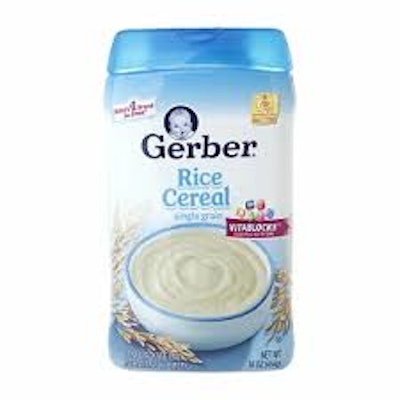

There’s no better example than Gerber’s replacement of a paperboard package that went relatively unchanged for some 50 years. The new package, for a line of powdered baby foods, is an extrusion blown HDPE with a pinched waist for easy gripping, gorgeous graphics from a full-body shrink-sleeve label, and a flip-top cap that not only vastly improves reclosing but also includes a scoop attached to the inside so consumers no longer have to dip their fingers through the product to find the scoop.

Also transformed is the package now used for MiraLAX, a granular laxative solution marketed by Bayer Group. When its previous packaging format was mimicked by store brands found in Walmart and the like, Bayer reengineered its package completely. Launched this spring, the extrusion blow-molded HDPE bottle has an oblong shape that makes it much easier to grip and pour than a round container. The injection-molded cap, meanwhile, has a special fitment placed inside during the capping process, which is done on an Arol 4-station rotary capper. Inside this fitment is a tear-drop-shaped opening that gets covered by an induction-sealed membrane. Good use of servo technology and an advanced vision system from Arol’s FT-Systems group helps ensure proper placement and orientation of all parts as this complex assembly takes place. Once again, a full-body shrink-sleeve label provides plenty of shelf impact.

Speaking of sleeve labels, Sleever International used Anuga FoodTec as a launch pad for shrink sleeve labels made from what it calls LDPET. The key is a low-density PET film (SI-TPEG/050 ZL) developed by Sleever International. Thanks to its density, the LDPET floats in the commercial recycler’s sedimentation tanks while the denser, heavier PET flakes sink. This makes separation of the two materials easier, which leads to purer RPET, says Sleever International.

The appearance of new examples of aseptically packaged beverages was, predictably enough, a highlight of Anuga FoodTec. Two in particular stood out: Fairlife from Coca-Cola and Toddynho from Pepsi. Fairlife is a 1.5-L bottle of milk that is run through a unique filtration process resulting in a product with 50% more protein, 30% more calcium, and half the sugars of regular milk. Plus it’s lactose-free. Costing more than twice as much as regular milk, it reached store shelves in February. Industry wags have already dubbed it “Milka-Cola.” Aseptically filled on a GEA system in Coopersville, MI, the product has a 90-day shelf life. It’s merchandised in the refrigerated case.

While Fairlife is aimed at a 20- to 40-year-old demographic, Pepsi-Co’s Toddynho goes for the tweens and young teens of Brazil and other South American countries. It’s a 270-mL bottle of pre-mixed chocolate milk drink said to have high nutritive value. Sold previously in an aseptic juice box format, Pepsi-Co decided that that format would be looked down at by kids older than 10 because, after all, a juice box is something a toddler drinks from by way of a straw. The plastic bottle, on the other hand, is cooler and can be reclosed and stashed in a backpack in case the consumer wants to finish it later. Filled on an aseptic system from Stork, the product has a six-month shelf life. It’s merchandised at ambient temperatures in supermarkets and in a chiller cabinet at the C-stores and abundant small shops of South America.