At a time when consumer packaged goods companies’ environmental credentials around packaging are being closely scrutinized, it’s not uncommon to hear a brand say that sustainability is part of their DNA. For L’Occitane en Provence, a French luxury retailer and manufacturer of cosmetics, wellbeing products, and fragrances made from natural and organic ingredients, this claim is verifiable. Upon the company’s founding in 1976, it offered a bottle return system and since then has added eco-refills, in-store collection, and refill fountains to its offerings. In addition, it has also standardized the use of just three plastics—polypropylene, polyethylene, and PET—to ensure its packaging is recyclable.

The company has also been a pioneer in the use of recycled plastics. According to L’Occitane en Provence R&D Packaging Director David Bayard, in 2008, L’Occitane was the first to put shampoo in a 100% rPET bottle. Looking toward 2025, the company has committed to having 100% of its retail bottles in 100% rPET.

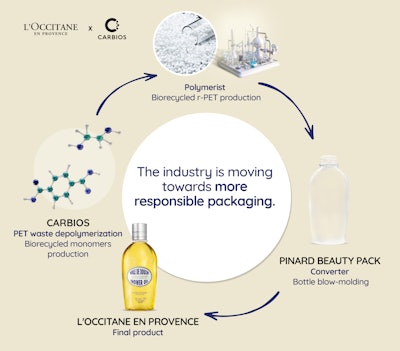

Carbios’ enzymatic depolymerization process allows for a completely circular system for PET packaging.

Carbios’ enzymatic depolymerization process allows for a completely circular system for PET packaging.

“So far, we are around 55 to 56%, but we have some limits with mechanical recycling,” shares Bayard. “The main limit for us is color. As soon as you mechanically recycle the resin, there is an impact on color. And when we have a package for a product such as body lotion, for instance, which is mainly white, the impact for us in terms of image is not acceptable.”

Recognizing this challenge, in 2021, L’Occitane invested in Carbios, a French biotechnology company that uses enzymes to depolymerize waste PET, purifying the resulting MEG (monoethylene glycol) and PTA (purified terephthalic acid) monomers and then using them to create new, virgin-quality PET. Interestingly, because depolymerization is a closed-loop recycling process, the material can be traced from feedstock to monomer, therefore it does not require a mass-balance approach to calculate recycled content.

In May, Carbios reported that it had successfully piloted a clear, 100% rPET bottle for L’Occitane’s almond shower oil. Bottle converter Pinard Beauty Pack produced the bottle using L’Occitane’s existing molds with no changes required to the equipment. Explains Bénédicte Garbil, SVP Corporate Affairs & Sustainability for Carbios, the pilot was a necessary step in scaling up the process, “especially to validate the material conversion and to confirm that the quality level corresponds to L’Occitane’s requirements.”

Carbios’ depolymerization process, currently taking place at its demo plant in Clermont-Ferrand, France, is unique in that it is the only one that uses enzymes. Says Garbil, “This makes it a soft biological process without the use of solvents, a process that depolymerizes PET in water under the action of our enzymes.”

He adds that, thanks so its highly selective enzyme, optimized for efficient PET degradation, Carbios’ depolymerization technology can handle all types of PET waste, including colored, multilayer, or textile waste that cannot be recycled with current technologies.

Bayard says that L’Occitane was attracted to Carbios’ biorecycling technology because of its impressive LCA. “When Carbios performed its first lifecycle analysis, it found a decrease of 57% in carbon emissions versus [the production of] virgin PET,” he says. “It [the biorecycled PET] is a way for us to speed up our commitment to switch all our bottles to rPET.”

Having concluded validation of the 100% rPET bottle using Carbios material, L’Occitane plans to bring a product to shelf by year-end 2025 in the packaging, with the material coming from Carbios’ demo plant. With the completion of Carbios’ first commercial scale plant in Longlaville, France (expected in 2026), L’Occitane plans to convert the rest of its PET packaging to the material.

| Read about another unique molecular recycling project in this article, “L’Oréal Pioneers Bottle Made from Industrial Emissions” |

According to Bayard, once L’Occitane has moved all of its rigid PET packaging to the enzymatically recycled PET, it will reduce its use of virgin PET by more than 500 tons per year, as well as eliminate its use of mechanically recycled PET by 500 tons as well. PW