This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Wipotec-OCS, a leading manufacturer and supplier of precision in-motion weighing, track and trace/anti-counterfeiting solutions, and X-ray scanning equipment, will introduce new predictive maintenance functions for its line of high-precision catchweighers at MODEX Booth #B7232, March 28-31 in Atlanta. The analytics-driven solution allows parcel processors to proactively predict when its catchweighers will need maintenance, resulting in well-planned tune-ups that minimize downtime.

The new tools essentially allow catchweighers operators to “see the future,” providing a more accurate picture of when maintenance will be needed. The result is a data-driven ability to anticipate when a component actually needs repair or replacement, rather than the comparative guesswork of general guidelines and recommendations.

With the Wipotec-OCS predictive maintenance solution, a potential part failure can be detected at an early stage, then proactively prevented without interrupting operations. The system also allows parts to be utilized for their actual lifespan rather than their recommended one. Finally, much of the data obtained from implementing predictive maintenance software—including optimal throughput for the most accurate checkweighing— can be applied to boost overall equipment effectiveness and productivity.

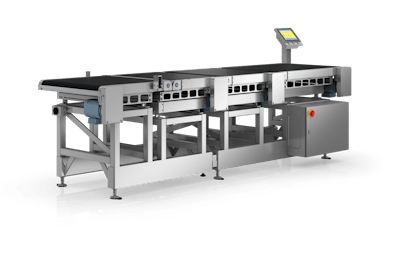

Wipotec-OCS catchweighers feature the company’s electro-magnetic force restoration (EMFR) weigh cells, a next-generation technique that guarantees optimal weighing results even at high line speeds. The machine features a revolving weighing system that segregates each product, weighs it independently, and returns it to the line, providing exemplary accuracy even at high speeds.

The company’s HC-FL-T triple scale catchweigher combines three hardware scales into six virtual ones, each capable of operating independently—a feature permitting product gaps as narrow as 10 in.

The HC-FL-T’s triple scale design delivers a 60% throughput increase at the same speed as a double scale design. Depending on product length, the triple scale catchweigher can weigh as many as three products simultaneously. The HC-FL-T can accurately weigh up to 19,000 parcels/hr at transport speeds up to 670 ft/min. The use of a high-tech EMFR weigh cell delivers NTEP weighing accuracy of 50 g, even when running at top speed.