This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

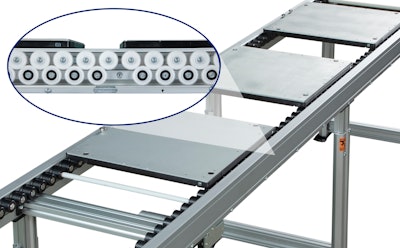

Dorner's ERT250 edge roller pallet and tray handling conveyor uses rollers to move pallet conveyors smoothly with no friction (a byproduct often seen in belt-driven platforms). It uses pallet sensors and control logic to determine when a pallet is free to move forward, or if a pallet is stopped downstream. If a pallet is required to stop, it will stop in the next zone. Motors operate only when pallets advance forward or reverse. Multiple zones can be created on a single conveyor. Using zones reduces the number of stacked-up pallets, while still providing effective accumulation capabilities.

PACK EXPO Las Vegas and Healthcare Packaging EXPO (Sept. 27-29, Las Vegas Convention Center) will reunite the packaging and processing community. With over 1400 exhibitors, no other event in 2021 will bring together a more comprehensive gathering of suppliers offering new products, technologies and solutions. Attendee registration is now open.

The ERT250 is also ideal for applications calling for pallet or tray handling with no- and low-back pressure accumulation, and cleanroom applications such as medical product or device manufacturing, assembly, packaging and others.

Technical specifications for single and multiple zones on the ERT250 include:

• Widths 100 mm to 960 mm wide

• 38 mm diameter rollers on 50 mm centers

• Loads up to 250 lb/pallet or tray

• Loads up to 15 lb/ roller

• 150 mm long tray minimum

• Speeds up to 37 m (121 feet) per min

• Aluminum frame with two T-slots

• Energy efficient brushless DC gearmotors and controllers; motor controllers use Ethernet IP for easy communication

• Reversible

• Automation modules (240 mm width minimum)

• Navigate 90° and 180° corners

• Lift and transfer

• Lift and locate

• 90° pusher