This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

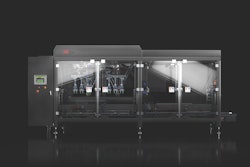

Cardinal Agri has been using Liquibox’s Intasept filling machine for bulk bags ranging from 200L to 1,000L for industrial applications. By adding one more Intasept aseptic filler, it is now able to produce 20L aseptic bags at the 2 bags/min rate.

This is the first filling machine entirely designed and manufactured by Liquibox Thailand, as the company is expanding its global footprint after the acquisition of the DS Smith flexible packaging business. Prasert Ariyaarpakul, Liquibox Bangkok plant manager, explains: “We aimed to address all the customer needs while designing this filler, such as adapting it to their existing conveyor and the peculiar plant layout. We also created a tailor-made solution for the drums to be placed and filled on the side, which reduced the changeover time by 60 percent.”

“I would like to thank Liquibox New Zealand filling systems team for guiding me and the local team throughout the process as we were able to deliver a high-quality custom solution that integrates seamlessly with Cardinal Agri processes, maximizes efficiency and delivers sustainable performance,” says Prasert Ariyaarpakul, Liquibox Bangkok plant manager.

“We have worked with Cardinal Agri for almost five years, supplying all of their bag-in-box bags and providing dedicated technical support for their bulk bags filling machine,” says Kavalee Kwaengsobha, Business Development Manager at Liquibox. “By building a trusted partnership beyond the factory floor, we were able to quickly respond to their needs with an innovative solution that helps them carry out their mission to support and grow small farmers.”

Both Liquibox filling machines are located in Cardinal Agri’s state-of-the-art factory on the island of Palawan—where up to 300MT of coconut is dehusked, processed, and packaged every day.