This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The modification included a 51 ft mass flow transport conveyor section and a 54 ft long by 10 ft wide accumulation table to hold backed-up or accumulated product to nearly 14,000 cans at a required rate of 900 cans/min. NOTE: This video has been intentionally blur-time-lapsed for proprietary purposes.)

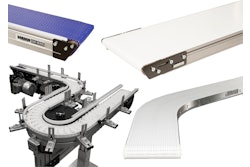

Accumulation tables, like this one from Multi-Conveyor, increase line uptime by allowing conveyor systems to store product so that the upstream equipment, in this case a filler, can remain operational at full speed if downstream equipment is stopped. When clear, the table automatically reintroduces the accumulated product to match down-line equipment surge rate until the table is emptied

This project incorporated raised rib chain to provide a smooth transfer onto and off of the table and a heavy solid stainless steel floating sweep arm to assist in table filling and emptying.