Automation can be an effective way for manufacturers to keep up with product demand, save costs and labor, and improve efficiency. These benefits and more are what representatives from ECOS, a California-based eco-friendly cleaning product manufacturer, and Garrett Brands, the company behind Chicago’s Garrett Popcorn Shops and Frango Chocolates, highlighted during Formic’s Automation Showcase in Woodridge, Illinois on Jan. 23.

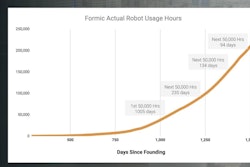

Formic is a provider of Robots-as-a-Service (RaaS) automation for U.S. manufacturers. The company collaborated with the Chicagoland Food & Beverage Network to bring together several packaging and processing companies to late January’s event.

Mike Martini, quality director at ECOS, started by giving other brands a look inside his company’s process of adopting and scaling Formic’s automation machinery.

Martini began by describing the challenges that led ECOS to consider automation.

“Every one of our facilities has at least one, maybe two lines of producing a 50-lb container of laundry soap continuously for at least one shift, some two shifts. After the pandemic, we struggled [to hire], and the [employees] we did hire, we struggled communicating with,” Martini said to the group of company representatives attending the showcase.

Martini further explained that ECOS dealt with some employees having back injuries from heavy lifting. The company had a policy for employees to change positions every hour to prevent ailments, but automating the task would help improve safety and efficiency.

ECOS asked Formic for a recommendation, and renting an industrial palletizer seemed to be a strong fit for the cleaning product manufacturer.

“Our experience has been wonderful. I would say the business model that Formic is offering is perfect for our organization,” Martini stated. “We don’t have technical people all around. We know packaging. But making that packaging and doing all those things with it, we don’t have that expertise. The partnership we have developed [with Formic], we went from one [palletizer] in Washington, and now we’re going to be close to a dozen units and looking at additional automation for other processes.”

Automation made easier

Formic allows manufacturers to rent machinery and pay month-to-month as needed. Manufacturers have access to 24/7 tech support and can swap equipment based on production needs while maintaining a fixed price.

ECOS has been satisfied with its experience with Formic and has rented more palletizers. Outside of the burdens of heavy lifting, consumer input was a driver for ECOS to add more units, Martini stated. The increased number of palletizers helps the company keep up with consumer demand.

Furthermore, Martini said that ECOS meeting their cases-per-hour standards with the first palletizer was another factor prompting them to scale up. One of the company’s limitations is the ability to fill, which limits how many cases per hour they can achieve. However, Martinti says the palletizers are “never down” when the company uses them, maximizing uptime. Finally, Martini stresses that when the company has any questions about the palletizers, there are technicians available to come on site.

ECOS is not the only brand recognizing the benefits of Formic’s services. Garrett Brands has a palletizer arriving at one of their production facilities in March, according to Jim LaRocco, director of manufacturing and fulfillment. The palletizer will help the facility pack products from two different production lines.

“Having people on site to manage [robotics] is tough. [Formic] has the solution, being able to wire into [automatic palletizers] and know exactly what’s going on. So, the technology piece, we don’t have to deal with. That’s a huge part for us,” LaRocco told Packaging World.

LaRocco says saving capital dollars and being able to rent machinery on an as-needed basis is a huge benefit.

“I’ve bought robots for other companies, and you’re spending five, six hundred thousand dollars and another hundred thousand on install and programming… [Formic] is going to deliver [the palletizer], and they’ll be here to make sure it works. And so, I don’t have to find a control tech to work on a robotic. It’s really difficult in today’s environment. [Formic] has figured that out, and they lease their equipment, so it’s awesome,” LaRocco continued.

Reliable and accessible tech support along with flexible renting options stand out to manufacturers using or considering Formic’s services. The standard industrial palletizer seems to be one of the most popular choices amongst renters. It features a small footprint, an ability to be deployed rapidly, and contains a user-friendly Human Machine Interface (HMI) operation.

As automation and robotics continue to become integral for packaging and processing companies, contractors like Formic will be on their radar to fit production needs.