This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

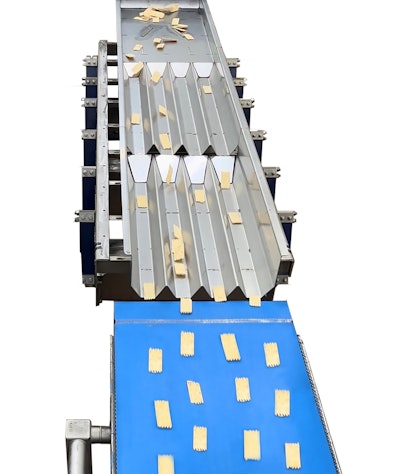

Each series of integrated conveyors meters separates, singulates, and/or aligns product, depending on the application, to provide the optimal product separation, speed, and orientation for ideal presentation to the robotic system for pick-up. By minimizing hand packing, these new systems help increase production efficiency, reduce labor, and improve sanitation. Key Technology designs, builds, then tests every integrated conveying system to identify the optimal speed, stroke, lane widths, and step sizes to consistently present the processor’s products to the robot’s end of arm tooling. Suitable for primary or secondary packaging, these systems can handle frozen foods such as potato products, meat, poultry and seafood as well as dry products such as cookies, pet treats, confectionaries and snacks.

The integrated conveying system often begins with an optional shaker or belt conveyor to meter product, if needed. Then, a separating shaker evenly spreads product, followed by a singulating shaker that directs product into single-file lanes. The next shaker aligns the product in the correct direction, if required, and achieves the optimal speed to feed one or more pick-and-place robots, which are installed on one or both sides of the conveyor. Products that are not picked up by the robots can either be collected in a hopper or recirculated to the beginning of this system.

Key’s conveyors are designed for superior sanitation with stainless-steel bed surfaces, open designs, and oil-free drives. When a processor automates primary packaging, sanitation is further enhanced by eliminating the manual handling of unpackaged products in the packing process while reducing the chance of accidental foreign material contamination by a worker.