This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

It is designed and built to FDA sanitary standards and features heavy-duty, fully welded stainless steel washdown construction.

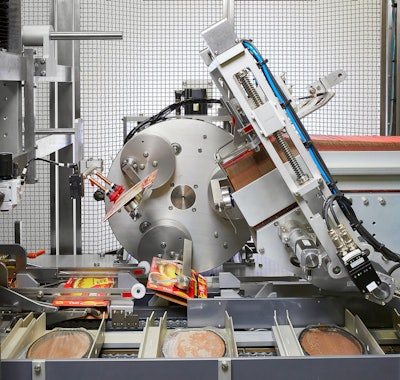

PMI KYOTO’s all-servo driven cartoner has a compact design, providing a small footprint and making it easy to integrate. Quick and simple changeovers are performed at the touch of a button on the HMI making it ideal for a variety of SKUs and suitable for CPGs and contract packagers. With built-to-last, quality construction and materials, this system features full-height guard doors with interlocked stainless frame. The system can run cartons or sleeves at speeds up to 240/min.

Also ideal for CPGs and contract packagers is the system’s flexibility to ramp up or down production as needed. For smaller runs or lower output, a hand-load option is available. When production needs to increase, simply add on a robotic infeed section for higher speeds and added efficiency.

PACK EXPO Las Vegas and Healthcare Packaging EXPO (Sept. 27-29, Las Vegas Convention Center) will reunite the packaging and processing community. With over 1400 exhibitors, no other event in 2021 will bring together a more comprehensive gathering of suppliers offering new products, technologies and solutions. Attendee registration is now open.

“We’re excited to bring a flexible and efficient solution to the market,” said Branko Vukotic, PMI KYOTO President. “By offering a washdown horizontal system for frozen foods and dairy, we are able to address the needs of additional industries and bring more value to our customers.”

Additional features include a high-speed servo-driven rotary carton placer with pre-break, articulating product buckets with barrel cam pusher heads, servo flap tuckers with cycle stop mode-positive flap closing device, Nordson hot melt glue system and an Allen-Bradley system control platform and HMI.