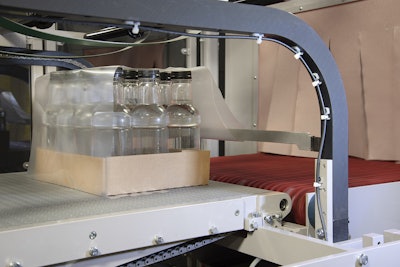

This includes trayed packaged food products, pet foods, dairy products, mixed multipacks, and other packaged products, as well as untrayed single products and multipacks of containers.

The primary benefit of this system is its ability to deliver reliable, repeatable wrapping performance at a fair investment value. It operates at medium speeds in a real-time production environment, and has the ability to accurately control print registration. A welded tubular frame controls vibration to ensure consistent wrapping output and production throughput.

The servo-driven inline system can be easily integrated into an existing production line, and is designed to handle products up to 16 in. in length, 12 in. high and 20 in. wide The system wraps using 1.5 to 3.0 mil film in segments up to 55 in. long and 22 in. wide. The SRW 22-45 can wrap products using either clear plastic film, random printed or print registered film. Trayed products can be wrapped in corrugated trays or on flat pads. During the servo-driven wrapping process, products do not stop, but are in continuous motion as film is applied and cut, maximizing productivity. A high-efficiency shrink tunnel completes the wrap sealing process.

The SRW 22-45 system’s welded tubular steel frame has a powder-coated surface finish. Legs are threaded to be adjustable up to 2 in. for system leveling. Available additional options include a film loading cart and an inline cradle splicer for speedy film changeovers. The EDL SRW series is designed, built and supported from the company’s Green Bay facility with features and details that address packagers’ need for reliable operation and repeatable performance in medium speed shrink bundling with print registration capabilities.