ESS Technologies’ TaskMate Robotic Case Erector/Loader is integrated with the Xyntek-Antares Turn-key Serialization solution, which features the Antares Tracking System software and the Omnivision 360° Bottle Tracking System for serialization and aggregation, creating an automated case erector / loader with integrated track & trace capability.

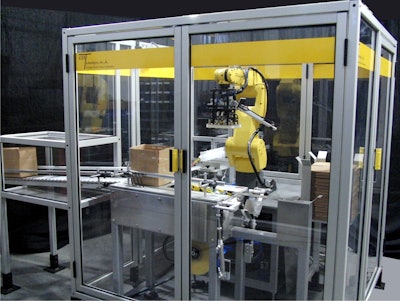

The TaskMate Robotic Case Erecting and Loading System integrates a FANUC LR Mate 200iC/5L multi-axis robot with ESS-designed end-of-arm tooling (EOAT) to create a compact and low-cost case packing system. Other FANUC robot models may be specified, depending on the required payload. Vacuum cups on the special robot EOAT pick an RSC case blank from a magazine. The case is erected, the bottom is taped closed, and the case is placed in the loading position.

The Xyntek-Antares Omnivision 360° Bottle Tracking System will read the unique serial number on the labeled bottle and aggregate it to a “dummy” code on the bottom of the item. This aggregation will enable 100% verification of the bottles as they are packed by the TaskMate Robotic Case Erector into the case.

After the bottles leave the Xyntek-Antares Omnivision 360° Bottle Tracking System, they are collated into a 4x3 pack pattern. The robot will then pick the entire pack pattern and load it into the case. Right before placing the bottles in the case, an integrated Cognex high-resolution smart camera will read all of the bottom codes of the bottle bundle as they are being packed into the case by the robot. The Xyntek-Antares Tracking System software will confirm the unique serial numbers based on the pack pattern and print a case label to complete the bottle to case aggregation.

The robot EOAT then pushes the loaded case onto an exit conveyor; the case may be sealed manually, or secondary closing systems can be integrated. The system handles up to 5 cases/min., providing an automated alternative to manual case packing processes. The custom designed EOAT can be configured to handle a wide variety of products.