This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Packed inside its rugged stainless steel frame are a host of production-proven components that provide continuous and reliable high speed operation, including the metering belt case feed powered by a substantial 1 hp motor that ensures precise case transfer for synchronized flap folding and sealing. The rotary flap tucker smoothly breaks the score of the leading inner flap for accurate folding and securely tucks the trailing flap. A-B-C Packaging’s exclusive contoured, cast aluminum flap folders fold the outer flaps precisely on the scoreline.

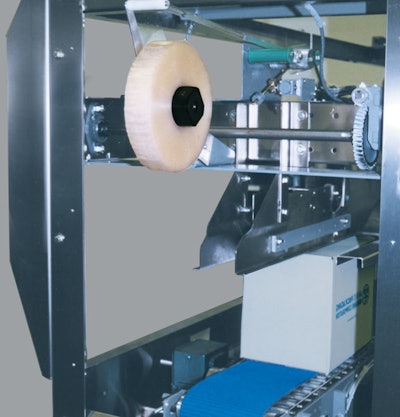

The tape system is designed for minimum downtime, with the tape head mounted outside the machine frame for quick and easy tape roll changes. A “roll empty” sensor eliminates tape head rethreading- the sealer stops when the roll is depleted, and the new roll can be simply attached to the end of the previous roll. Clear, high visibility gull wing doors enclose the machine and stop the sealer when opened to allow quick access to all operating components.

The Model 436’s compact design (10’ long) and wide case range (Min: 8”L x 6”W x 4” H Max: 24”L x 17”W x 17”H) provide line flexibility for today and the future.