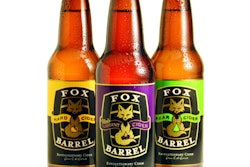

A new paperboard gift box for 750-mL glass bottles of champagne spawned an entirely new end-of-line packaging solution at the Reims, France, facility of Veuve Clicquot Ponsardin (VCP). I was fortunate enough to be part of a December 10 press tour through the fascinating and historic plant, where the one of the world’s most heralded champagnes is made. Here are the essentials of the robotic solution supplied by Cermex.

Called the Design Box, the new package is a gift box with a slide-out compartment that gives the package an almost interactive quality. Four key requirements made the development of the new packaging equipment necessary:

• To the extent that end-of-line technology would allow, VCP wanted to eliminate scratching or scuffing of the Design Box and of the corrugated shipper.

• VCP wanted to address ergonomic issues wherever possible.

• VCP wanted to reach speeds of 8,500 bottles/hour, which is best in class among its peers.

• VCP wanted the following: maximum automation and as little human intervention as possible; servo-controlled actuation rather than pneumatics wherever possible; simplified operation; fast and easy changeover; and ease of maintenance.

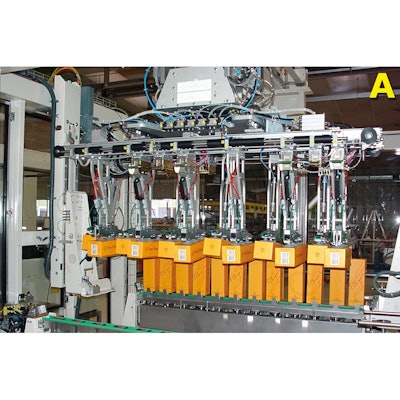

Cermex met these requirements by combining two robotic systems: an AN110 gantry packer and a WB45.80 wraparound case packer that has two Fanuc M710 robots integrated into it. The AN110 gantry packer, designed and made by Cermex, handles high speeds with payloads of up to 250 kg. It essentially collates these formats:

• 6 bottles each in a Design Box, where three Design Boxes are atop three others

• 12 bottles each in a Design Box, where six Design Boxes are atop six others

• 6 bottles aligned head-to-toe in corrugated trays, where a tray of three bottles sits atop another tray of three bottles

• 12 bottles aligned head-to-toe in a corrugated tray, where a tray of 6 bottles sits atop another tray of six bottles

The end-of-arm tooling on the AN110 gantry packer is changed automatically at the push of a button on the operator interface panel. Tooling not in use is placed on a rack and the new tooling is pulled from its rack and placed into operation.

In the photos shown here, Photo A shows the AN100 picking bottles in their Design Boxes and placing them in the transport device that advances them forward to the wraparound case packer. Photo B shows the AN100 picking unboxed bottles and placing them in corrugated trays that are then advanced forward to the wraparound case packer.

The WB45.80 wraparound case packer also is equipped with automatically changed end-of-arm tooling. Photo C shows it stacking Design Boxes three layers high for a total of 12 per case. Photo D shows it stacking trayed bottles (in their head-to-toe pattern) two layers high for a total of 6 per case.

Also worth noting is the product orientation capabilities on the line. For example, bottles are turned via a vision system. The bottles are positioned on a mobile stand, and a camera placed above the bottle reads the position of the label and rotates the stand until the bottle is correctly oriented.

Near the end of the line is a Cermex P432.20 automatic palletizer that features a servo-driven collation table. Stretch wrapping of pallets brings the end-of-line solution to a close.

Compared to the more traditional folding carton it replaced, the Design Box requires more paperboard material in its makeup. But VCP claims it is greener than its predecessor for three reasons:

• Advances in construction, combined with the inclusion of an ingenious F-flute corrugated, permitted the elimination of a polymer coating that was needed on the former gift box.

• The newly designed wraparound corrugated shipper is source-reduced compared to its predecessor.

• The paperboard used by gift box converter SCA Packaging and by corrugated supplier Seybold is FSC certified.