This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

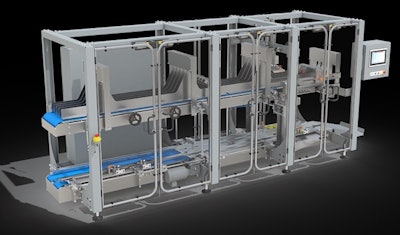

Serpa, a ProMach brand and a manufacturer of packaging technology and full line integrations, is expanding into new markets with the introduction of its breakthrough drop packer. The new DP260, part of the DP Series, is designed for the food, personal care, and household markets and will be unveiled at Booth W-1148 during PACK EXPO Las Vegas, Sept. 29-Oct. 1.

The DP260 is a cost-effective automated case packing solution that offers single and tandem drop options and capable of achieving speeds of up to 60 cases per minute. Serpa’s new drop packer is designed for efficiency and ease of use, making grid changeovers, lane and case size adjustments and maintenance operations quick and simple for the user.

The DP Series drop packer accommodates a variety of products of varying sizes that can be arranged in different packaging formats, from sauces, condiments and dressings to liquid detergents, disinfectants and household chemicals.

Key features and benefits of the drop packer:

- Intuitive Design and Increased Productivity: The machine’s servo-driven case elevator ensures a gentle product drop into cases, reducing the risk of damage.

- Rapid, Tool-less Changeovers: With a lightweight product grid mounted on a slide-out shelf, complete changeovers can be done in minutes without tools making the task fast, simple and repeatable for a single operator. This significantly reduces downtime and ensures production uptime.

- Machine Durability and Low Total Cost of Ownership: Built with a robust and simpler design, the drop packer is made to last over 20 years with reduced short- and long-term maintenance costs.

- Greater Functionality and Ease-of-Use: With a maintenance-friendly design, operators have complete access to all machine components for ease of operation, upkeep and service— ultimately minimizing downtime.

- Easy Case Clear Out: With easy operator access for clearing out cases, the line can be kept running at peak efficiency and guaranteeing 98% machine uptime.

This marks Serpa's first entry into the drop packing segment, enabling the company to offer a more complete range of end-of-line packaging solutions from the filler through the stretch wrapper.

“Serpa has been providing customers with a wide range of case packers with different loading types to meet their product needs. Now we’re expanding our portfolio to add a standard drop application to accommodate even more packaging requirements,” said Justin Neece, Serpa’s Vice President and General Manager. “By incorporating our tried-and-true machine design concepts of rapid, consistent changeovers, we’re able to offer customers a new drop packer solution that’s easy to use with speed and flexibility in mind.”

The DP260 being exhibited at PACK EXPO has already been purchased by Clean Control Corporation and will be shipped to their Warner Robins, GA, facility after the show. The drop packer will be used to automate the production line for its OdoBan 32-oz disinfectant spray bottles.

“Currently, our case packing process for this product is fully manual and labor intensive, making it one of the hardest jobs at the plant,” said Nic Bekkers, Technical Manager of Clean Control. “This new machine will enable us to mitigate some of the bottlenecks and pain points we see on the line and increase our productivity by almost double.”

The new drop packer can be integrated with other ProMach offerings on the production line, from upstream filling solutions to downstream palletizing. Also available in the series: a pick-and-place robotic application more commonly seen in the wine and spirits markets.