An especially timely feature in the showroom was an ideal solution for the use of its SVP process system for the production of potential Covid-19 vaccines. The equipment from the modular construction kit is available for delivery within a short time and can be ramped-up immediately.

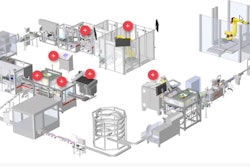

Solutions for Syntegon liquid pharmaceutical filling systems ranged from small and micro batch sizes to high-performance machines include the MLD cartridge filling equipment. Combined with more than 25 years of experience in isolator technology, Syntegon offers everything from a single source, including bio-decontamination and air-handling technology as well as the qualification and validation.

This line competence is rounded off by advanced inspection technology, like Syntegon’s AIM 3000 series, which utilizes high-resolution CMOS cameras with high-speed interfaces to detect particles and cosmetic container defect, while an optional module offers 100% Container Closure Integrity Testing (CCIT).