Even companies whose names are recognized worldwide must periodically re-evaluate equipment in order to maintain market dominance. When one such manufacturer learned that an outdated palletizing robot gripper had to be replaced, they turned to Premier Tech Chronos for a retrofit.

One problem that needed to be solved was a lack of reliability. Because the plant’s existing palletizing robot was manufactured by a company that outsourced components, the customer might wait months for replacement parts.

The second problem was that suction cups on the robot’s original end-of-arm tool (EOAT) deformed bags by creating a pyramid one-half to one-inch high in the center of each bag. Not only did that result in unattractive bags, but it also created palletizing problems because deformed bags occupy more space. The resulting pallets were unnecessarily tall, requiring more wrapping material and decreasing stacking efficiency.

These problems could be remedied by Premier Tech Chronos, the customer realized, since it was pleased with the performance of the EOAT that Premier Tech Chronos had designed and installed elsewhere within the same facility. It was decided that the outdated vacuum gripper on the palletizing robot’s arm would be replaced by a Premier Tech Chronos finger gripper.

One advantage of the finger gripper is that because it lifts bags from underneath, it transfers bags without deforming them, producing uniform pallets. This makes it possible to create stacks that are four pallets high, which is more efficient than the shorter stacks that occupied more space in the customer’s warehouse before the retrofit.

Another advantage of lifting bags from underneath is that the possibility of dropped bags and resulting material loss is reduced. Plus, the greater placement precision provided by the gripper can increase throughput by as much as 20 percent compared with the vacuum model. The gripper increases the line’s flexibility as well, by palletizing a greater variety of containers than the vacuum EOAT it replaced.

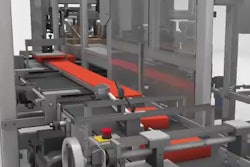

The finger gripper permits automatic bag handling from the pick-up point to the pallet, providing support under each bag and quick, symmetrical release at the drop point on the pallet. Just as important is the design of this tool, which cradles filled bags and provides support to ensure bags are not deformed. Designed to accommodate a broad range of bag types, the automatic bag-width-adjustment servomotor that was installed allows the finger gripper to be adjusted to accommodate bags of various widths during the same run. This increases process flexibility, efficiency, and productivity.

The pick-up conveyor has a smooth PVC coat on its conveying side to ensure bags aren’t snagged or ripped. Existing safety fences were upgraded with new safety modules in order to respect the customer’s budget while meeting current safety standards. A centralized HMI (Human-Machine Interface) was installed that greatly simplifies operations. Its one-point access for changing recipes limits the risk of human error, thereby reducing the potential for downtime.

Not only did this project allow the customer to simplify operations, update safety measures, increase throughput and acquire built-in reliability by retrofitting the existing EOAT with one from Premier Tech Chronos, it also simplified maintenance. Since all of the other robots at this facility were provided by Premier Tech Chronos and have finger grippers, only one finger gripper needs to be kept on hand as a replacement for all the robots. Although it’s unlikely that any of them will ever need to be replaced: Vacuum EOATs periodically wear out and must be replaced; finger grippers do not.

Another benefit came about because Premier Tech Chronos’ respect for the customer’s budget constraints created a two-phase approach: retrofit the EOAT first, with the option of installing a new palletizing robot later. This affords the customer flexibility in timing and budgeting.

Retrofitting “was challenging,” reports Louis Brochu, Client Services Engineering Supervisor at Premier Tech Chronos. “But thanks to customer collaboration and engineering thinking that envisioned a creative and cost-effective solution, this project is a success.”