As a grower, packer, and shipper of organic produce, Earthbound Farm is recognized as an innovative industry leader. In April, 2012, they installed four Adept ClamPAC™ robotic systems from Adept Technology to case-pack clamshells.

This new technology gave them the dexterity and throughput they needed to automate what had been a manual operation. It also allowed them to design a new, more environmentally friendly clamshell that requires gentle handling.

Earthbound has been so satisfied with their first four ClamPAC systems, that they purchased four more.

"We explored several suppliers offering robotic systems. Adept was the only one we found that had a product that could withstand our rigorous sanitation routine," says Joe Torquato, director of engineering at Earthbound Farm.

"Our new robotic packaging systems improve the consistency of our throughput, which helps position us for continued growth. The technology is gentle and accurate; it reduces product damage and enhances the presentation of our clamshells in the case. It helps improve our work environment by eliminating a highly repetitive task. The labor cost savings gives us the ability to make this change that has widespread benefits."

ClamPAC is an integrated robotic solution that’s pre-engineered to case-pack clamshells. "Food processors like to find a single-source supplier that handles the entire process," notes Torquato. "Adept took on that accountability. They handled everything including our empty boxes. They learned all our SKUs and became very intimate with our process. They set the systems up to handle our clamshells and each case-packing configuration. They integrated their systems with our plant control network so we can control the operation remotely and gather data for reporting purposes. The integration went very smoothly.

"Our robotic case-packing systems consistently handle the clamshells more gently than laborers did and much more gently than our old drop-door case packers. Transitioning to the Adept systems gave us the gentle handing we needed to redesign our clamshells," says Torquato. "We used to have a shrink band on the clamshell, which we wanted to eliminate to take PVC out of the environment. Our new, patented clamshells feature a lid that's sonically welded to the tub. The Adept system is gentle enough to lift the clamshell by its lid and not break the easy-open perforation."

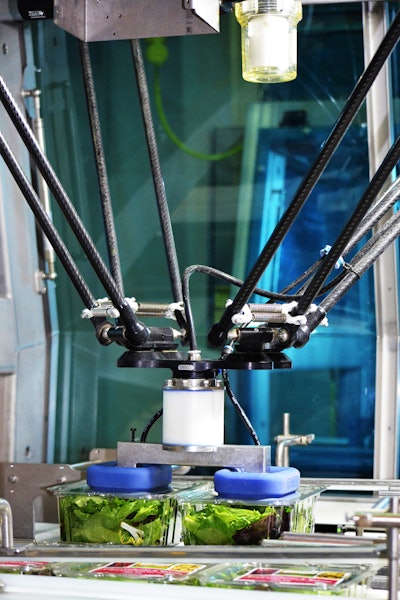

One component of ClamPAC that contributes to the system's gentle handling at high speeds is the design of its SoftPIC™ grippers. Selected specifically for each customer's range of products, SoftPIC grippers are made of soft silicon that conforms to the shape of the clamshell and provides a direct vacuum path to the product. For lines that handle multiple clamshell sizes or designs, the SoftPIC gripperscan be changed in less than two minutes.

"The ClamPAC systems nest the flanges of the clamshells during case-packing. This keeps the clamshells in a better position so they are less prone to damage during transportation. It also allows us to put the same number of clamshells into a smaller box, which reduces packaging materials," explains Torquato.

The first four ClamPAC systems at Earthbound Farm are case packing 5-oz clamshells filled with an assortment of washed lettuces into six- and eight-count cases. "ClamPAC tracks the box coming into the system and actually begins to fill it while it's still in motion. That's one way the system achieves its very high speeds while maintaining such gentle handling," says Torquato.

Earthbound Farm operates two production shifts and one sanitation shift a day, six or seven days a week. Electing to operate under the same high sanitation standards as dairy, meat and poultry plants, their sanitation routine is rigorous. "Adept's robotic packaging systems are designed with sanitation in mind, which supports an efficient sanitation process and leads to a clean, safe product," says Will Daniels, senior vice president of Operations and Organic Integrity at Earthbound Farm.

"The Adept ClamPAC systems have been very successful," says Torquato. "We wanted an integrated, turnkey system that would be easy to start up. We wanted the systems to be easy for our technicians to operate. And we wanted to achieve significant speeds and experience exceptional uptime. The Adept systems have delivered."