Experience is the best teacher, they say. And because this adage is as true in packaging as it is anywhere else, we used it as the basis for an exclusive online survey conducted this spring when Packworld.com asked for your packaging wisdom, insights, and ‘eureka’ moments. (See survey particulars, below).

SURVEY PARTICULARS

The survey was conducted by Packworld.com primarily through the month of April 2006 and drew 165 respondents. Unlike most of our online surveys, this one included an open-ended question: “Have you had a machine or project come to a standstill, then you or a coworker said ‘What if we...?’ and it saved the day? We’d like you to share that project-saving ‘eureka!’ moment with us. What we’re looking for are any breakthroughs of packaging ingenuity from yourself or coworkers that made lemonade out of lemons, either temporarily to save the day or permanently at your company.” More than 100 respondents shared their story.

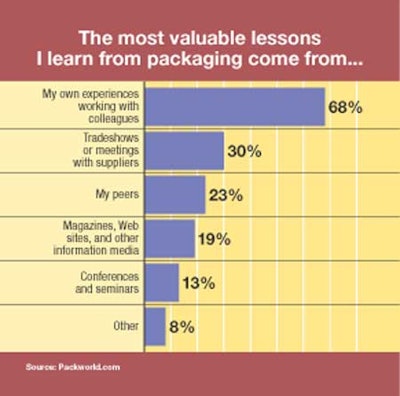

According to the survey results, nearly 70% said on-the-line experience provided the bulk of their packaging education, while 30% credited tradeshows and supplier meetings (see below). We also found that 60% have at least 10 years of packaging experience. In total, those surveyed collectively possessed an estimated 3ꯠ years of packaging experience—that’s a pallet load of wisdom. Frankly, the number of those who participated, 165, was low compared with most of our surveys. However, what struck us was your willingness to share your experiences when we asked for your breakthroughs of packaging ingenuity. In all, more than 100 shared their stories, a number of which were amply detailed. Some tales displayed a combination of ingenuity and resourcefulness, while others demonstrated remarkable persistence, like the package development engineer who needed dozens of iterations to make his carton design work (see sidebar page 52). Our hope is that these learnings will help you in your next project. The responses have been edited for clarity and space.

The value of adversity

According to Bill Bickford, design engineer, The Estee Lauder Companies, “Your question sums up around 95 percent of all of our projects in the past, present, and foreseeable future. I think there are few realistic packaging paradigms, and adversity is what truly makes greatness.”

We could not have said it better. It’s the perfect lead-in to our sampling of the tales of adversity overcome, of lessons learned through your experiences good and bad, of packaging lemonade made from lemons.

Most of you expect problems, and some even thrive on it. Said one respondent, “Every project I have encountered has fallen into this arena. These unexpected twists make the packaging job great, as it keeps the head from going idle.”

It’s said that you make your own luck. Such is this example from Bradley Wardrop-Brown, packaging technology and development manager for Simplot Australia Pty. Ltd. He characterized a recent project to develop a package for microwave-steamed sauced fish portions as interesting and unpredictable. “All the current packaging materials we had investigated had failed, and our team was becoming disheartened.

“What changed everything was a chance discovery, while working on another project, of a piece of film. It was attached to a leaflet stored for 18 months in our archives that had been picked up at the interpack tradeshow in Germany. The film was in experimental stages, but held promise. Within 16 weeks we went from idea to prototype to full commercial production to early 2005 introduction and solved a problem that seemed to have no easy solution. The lesson was that sometimes the solutions are already there, but you really have to know where to look for them. The product has been extremely successful and is continuing to grow every day, so this is one for the records—phew!”

Eureka moments

Eureka is Greek for “I have found it!” According to legend, it was uttered by Archimedes as he leapt from his bath after realizing how buoyancy worked. A true eureka moment can come at any time, such as in the middle of the night, or even at 30ꯠ feet as the following submission attests.

“My ‘eureka’ moment came years ago during an airsick attack on a plane. That’s when I realized that the airsick bag was exactly what I needed for a current microwave popcorn project. I forgot about being sick and then spent the next three months finalizing a supplier to make the bags I needed.”

I’m not sure I’ll ever look at a bag of microwave popcorn the same way again.

Sometimes, the obvious isn’t. “A carton former was acting up and we could not figure out why until an associate asked me if I had checked to see if the machine had been centerlined recently,” said one respondent. “He was right, nothing was centered. After going back to the basics, the carton former runs great. Sometimes the simplest assumptions get you in the worst trouble.”

Ingenuity usually isn’t about inventing something new, it can be about using a common item or material in a unique way, such as this example shows: “I was asked to adapt a freestanding package as a peggable package without losing product density or costing any more than our regular package. After many trials and errors, we had the idea to add ribbing to the package to strengthen it without adding costs. It worked, and the customer doubled its business for that product.”

“Keeping everyone in the loop enables you to avoid the ‘gotcha’ syndrome and gain acceptance, and it helps avoid injecting politics into the project.”

Resourcefulness is a common attribute among successful projects. “We had to produce a DVD with labels on the top and bottom of the package. Our lines would not accept such a labeler, so we built an inclined flipper to accommodate the second labeling step that permitted the company to accomplish the project.”

One respondent told of the challenges of designing a pack that would be protective and user friendly: “What I found was that there are always strategic points where less is more: Using dead air space [in the packaging] to my advantage often did more than trying to cushion every possible contact point.”

Another lesson gleaned from your input is that theory and reality can be worlds apart. “We had a project in which we were trying to manipulate a material. On paper, it should have worked, but the material failed after testing. We ended up finding a better material that was less expensive and significantly stronger.”

A shift leader at a Canadian brewery pointed out that his job is a series of eureka moments. “Most of the time we’re in production it is left up to the supervisor and myself to deal with the mechanical aspects and other troubleshooting that may be needed to see any projects go smoothly. Many times things change hour-to-hour and we need as many ‘eureka’ moments as possible, sometimes just to get through the day.”

Lessons learned the hard way

Alas, in the real world, not every story has a happy ending, though a valuable lesson can be learned.

“A packaging project took an unpredictable turn because a supplier did not understand the regulatory compliance of his own product,” wrote one respondent. “He recommended materials as being compliant that were not. It caused chaos. The lesson learned: Never overestimate anyone’s capabilities, and always double-check everything.”

Another relayed this timely advice: “Clearly identify the goal before you start working on a project. I worked on a project that had already been handed off twice before me. I lead the effort to launch only to learn that marketing had changed its mind about what the goal—the package—should look like. That meant nearly three years in total driving toward the wrong goal.”

I can sympathize. In my days as a research and development technologist working for a division of the R.T. French Co., I learned that getting marketing involved early in product development would save us major hassle later. I also learned it was better to get marketing’s instructions in writing.

Such was the plight shared by this packager, who offered advice both general and specific: “Don’t trust marketing and do not order case packers until you have production samples. On a new product rollout of a coffee bag, the original package was a firm, almost hard bag of coffee. Five case packers were ordered for the five packaging lines. Within three weeks of the startup of the first two lines, our marketing genius said the bag needed to be shinier and softer. The case packers needed the package to be firm, and to this day those case packers do not work that well.”

A dictionary or a second set of eyes can be an invaluable reference, as this story teaches: “I had taken over as the director packaging at Kmart. One of the graphic artists released artwork to the vendor, which printed packaging with the word ‘Bathrooom’ spelled with three Os three separate times. We immediately implemented a double-review of all artwork, which eliminated any typos for the next four years.”

Still another found that a dairy product filler had been installed but was not working well. He got to the bottom of the problem: A design flaw made by the filler vendor. Fortunately, he had withheld 5% of the payment upon successful running. It proved a crucial bargaining asset. “If I had not been holding the money, the vendor would not have worked with me to solve the problem.”

Another expressed the realization that there is a limit to cost reduction. “I made the decision to reduce material thickness over a period of time as a cost-savings move. As the project continued, we got to the point where the packaged product failed, causing multiple issues. In hindsight, the lesson learned was to go slow, and realize all the variables involved.”

Start with communication

Two commonly mentioned pieces of advice appeared frequently: To involve line operators in projects, and to have clear project goals and updates. One respondent expressed initial frustration on a project that then found its solution by getting out onto the production line. He then wrote: “I still believe in walking the lines and talking with the operators to get a true learning of how everything is functioning.”

Another concurred: “I am a firm believer in talking to the people who perform the job day in and day out. They are often overlooked as a viable resource.”

A packaging manager for a major brewery offered this wisdom: “Relay objectives to the line level and listen to the machinery operators. Their feedback can solve the hardest problem. Keeping everyone in the loop enables you to avoid the ‘gotcha’ syndrome and gain acceptance, and it helps avoid injecting politics into the project.”

Todd Molander, a senior packaging engineer with DePuy Orthopaedics, Inc., a Johnson & Johnson company, told of an assignment to develop a sterile medical kit that involved “an endless number of variations that didn’t work. The ‘eureka’ moment came when an operator from the pilot manufacturing area came over with her idea: Making changes to the inner tray that would allow more tubing to wrap around without kinking. This also eliminated multiple inner bands that had been used to hold the tubing sets together. This made the operation simpler and more repeatable and eliminated the labor time by one-third. The lesson learned: The value of asking for input from people outside of the package development team.”

When it comes to involvement and communication, this respondent may have said it best: “The most valuable lesson learned in the packaging business has got to be the importance of proactive communication. Time and time again, the value of getting and keeping all participating parties on the same page is extremely important to a successful outcome. The pool of resources that are available can be tremendous; however, the challenge is pulling together to keep everyone on the same page, and working towards a common goal. It sounds pretty basic, but in reality, when not done, it becomes one of the most common real root causes for failure.”

If there was a lesson I learned from this experience, it is that you, valued readers, are a wise and experienced group. Thanks for sharing, and we wish you all the best on your next project.

PRACTICAL ADVICE

This sampling of survey responses offers practical advice that otherwise may not be obvious.

· Communication, communication, communication.

· Proper planning prevents poor performance.

· I was slow to learn that breakthroughs in one industry always come from without.

· Make sure all parts ordered are the same, either in inches or centimeters!

· Always have a Plan B.

· Write down everything and anything on parameters of equipment.

· Whatever the speed or count requirements, always plan your equipment to run faster. It is inevitable that someone will want to increase production speeds as soon as the line starts.

· The most valuable lesson I have learned in 20 years of packaging experience is to build in extra time for delays and other challenges!

· The most important lesson we have learned over the years is to get all the right people together at the beginning of a project. The temptation to “get things moving” without taking time for this always results in a problem and waste later on.

See sidebar to this article: Persistence Pays