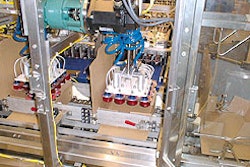

Regarding the servo-driven motion, Stan Johnson, Schneider Packaging’s vice president of engineering says, “this combination of horizontal and vertical motions, especially at high speeds, can be very damaging to the system’s timing belt. We needed to position a coupling between the case packer servo motor and the speed reducer/timing belt that would provide the horizontal linear motion and compensate for backlash and any offset between motor and speed reducer. “We considered bellows-type couplings, but ruled them out as they were too ‘mushy’ for this application. We needed ‘torsional’ rigidity in our design connection to eliminate any possibility of backlash that could affect the servo control.” Even a little “play” such as an extra ½ degree rotation in a rotary system, he adds, translates to “a lot of motion” in a linear system. Thus, the Zero-Max coupling provides the accurate motion transfer required.

Coupling smooths packer's pick-and-place motion (sidebar)

Tech talk

Feb 28, 2001

Machinery Basics

Annual Outlook Report: Workforce

Hiring remains a major challenge in packaging, with 78% struggling to fill unskilled roles and 84% lacking experienced workers. As automation grows, companies must rethink hiring and training. Download the full report for key insights.

Download Now

The AI revolution in packaging robotics is here

Robots that see variations, adjust grip pressure automatically, accept plain-English commands, and predict their own maintenance. Discover how AI is transforming packaging operations.

Read More

Downloads