Valley Media's original labeling/sortation/collation line is 300' L and contains literally thousands of photoeyes, motors, proximity switches, pushers, actuators, alarms, lights, and other components that make up the guts of the line. By contrast, the "average" packaging machine-say, a case packer-may be less than 20' L and may contain no more than a handful of such devices, or a couple dozen at most.

Yet both the line and a single machine share the same distinction: each is controlled by a single controller. While the original line runs successfully, Valley's experience shows that a single, centralized control for such a big job has its drawbacks (see main story).

So when the time came for Valley to order another line from Dorner, the manufacturing/systems integration firm rethought the controls after Valley communicated some of the improvements it would like to see.

Says John Kordic, senior vice president of operations: "They took that feedback and did their brainstorming on how to solve it and improve the line, and they came up with this [idea of distributed control]."

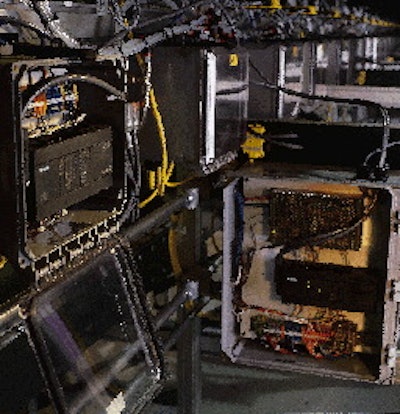

Rather than use one controller to manage the minutiae of sending and receiving signals to thousands of sensors, motors, switches, pushers and other devices on the line, Dorner suggested spreading out that burden among 126 micro PLCs.

On the new line, there still is a master controller, but it's a PC that communicates to the 126 micro PLCs. In turn, they communicate with the devices on the line in their immediate vicinity. The software that runs on the PC was supplied by Professional Control Corp. (Germantown, WI).

To understand how the new line differs from the old in terms of control, consider the old line analogous to a company of 5ꯠ workers with one manager. If that manager were out sick for a period of time, it's likely the company would soon grind to a halt.

The new line is like that same company with 126 middle managers. The lead manager needs only to interact with the middle managers to coordinate their actions. The middle managers, in turn, need only concern themselves with a small group of workers under their direction. Under this approach, neither the lead manager nor the middle managers are saddled with an excessive workload. And if one middle manager is out sick, the rest of the company can continue to operate. That's distributed control.

Jim Lysaught, director of systems engineering for Dorner, explains how distributed control works from the perspective of the line: "The PC pulls the data in from the [micro PLC that controls the] bar-code readers, determines where the product should go, and it issues the commands to the micro PLCs to say, 'Track this down to stacker number seven. Stacker number seven, I want you to do whatever you have to do to stack the product.' Then stacker number seven comes back and says 'I've got the part, and it's stacked.'"

Concludes Lysaught: "Even though there may be fifty steps in actually stacking the product [such as signaling pneumatic cylinders, gates and motors and monitoring sensors], the PC doesn't care about it, because those steps are controlled locally by each micro PLC."