This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

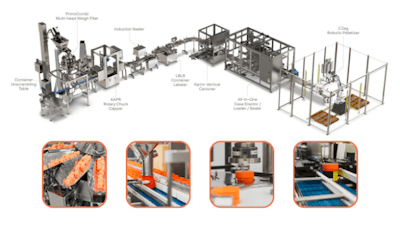

WeighPack Systems is proud to present its fully automated Turnkey Jar Filling, Capping & Labeling Line in Booth N-5906 at PACK EXPO International 2024, held from November 3-6 in Chicago. This advanced system provides a complete solution for weigh filling, capping, labeling, and packaging a wide range of rigid containers, offering unmatched efficiency and precision in a seamless production line.

Designed to handle containers made from plastic, cardboard, metal, or glass, the WeighPack Systems automates every step—from unscrambling and weigh filling to capping, labeling, and accumulating finished products. Ideal for industries dealing with gummies, candy, snacks, sliced fruit, nuts, spices, hardware, pet food and cannabis flower, this system offers a versatile and efficient packaging solution that enhances productivity across various sectors.

The PrimoCombi multi-head weigher delivers precise, accurate product weighing before efficiently dispensing the product into rigid containers using our container indexing conveyor. This conveyor ensures that each container is filled with precision, maintaining consistency and minimizing product waste.

The system’s KAPR capping machine is designed to accommodate a variety of container sizes and can operate at speeds ranging from 10 to 150 cycles per minute, depending on the container and cap specifics. Whether you are packaging small jars or larger containers, the KAPR family of flexible cappers ensure a secure and reliable seal every time.

For labeling, the LBLR wraparound labeling machine automatically applies adhesive labels to cylindrical bottles, containers, jars, and cans. This machine features an integrated conveyor, a robust stainless-steel frame, a color touchscreen interface, and quick-change label supply for streamlined operations and minimal downtime.

Once the containers are filled, capped, and labeled, they can be easily placed into cartons, cases, or trays, ready for case packing. The entire system is designed to operate efficiently and with minimal manual intervention, helping businesses optimize production and reduce labor costs.

Visit Booth N-5906 at PACK EXPO International 2024 to see WeighPack’s Turnkey Jar Filling, Capping & Labeling Line in action and learn how it can revolutionize your packaging operations.

And see these other solutions at PACK EXPO International 2024:

Turnkey Weighing & High-Speed Continuous Sanitary Vertical Bagging System

WeighPack Systems is thrilled to showcase its Turnkey Weighing & High-Speed Continuous Sanitary Vertical Bagging System at PACK EXPO International 2024. This system integrates the PrimoCombi multi-head weigher, an in-feed conveyor, and the VF1200 vertical form fill seal bagger, providing a comprehensive solution for efficiently creating, filling, and sealing packages at high speeds.

The in-feed conveyor allows for bulk product feeding at ground level, seamlessly transferring items to be precisely weigh-filled into bags as they are formed. The VF1200 is designed to handle multiple package formats and sizes, offering flexibility across various industries such as snack foods, confectionery, frozen foods, cheese, seafood, meat, and poultry. It works in perfect harmony with the PrimoCombi weighing scale, delivering reliable and precise packaging for a wide range of fresh or frozen products.

The packaging process begins with the VF1200 unwinding a roll of flat plastic film and shaping it into a pouch of the desired size using its forming tube. Once formed, the pouch is filled with product using the multi-head weigher, ensuring both accuracy and minimal waste. Once the product is accurately dispensed, the pouch is heat-sealed to preserve freshness, with the option to choose from various seal styles, including pillow or doy pouches. The system then trims the sealed pouch from the film, offering additional features such as tear notches or hanging holes, based on specific packaging needs.

Engineered for high-speed, continuous operations in sanitary environments, the VF1200 can achieve impressive output rates of up to 9,000 bags per hour, making it an ideal choice for both retail and club-size packaging applications. The machine’s vertical sealing bars operate in continuous motion, eliminating the need to pause the film during sealing and ensuring smooth, uninterrupted production.

Constructed with high-grade stainless steel, the VF1200 meets the highest IP standards for motors, heating elements, thermocouples, electronics, and touch screens, guaranteeing it can withstand high-pressure wash-downs and be sanitized to meet the strictest industry standards.

Visit Booth N-5906 at PACK EXPO International 2024 to see the Turnkey Weighing & High-Speed Sanitary Vertical Bagging System in action and learn how it can elevate your packaging processes to the next level of speed and sanitation.

V25 Bulk Case Filling System

WeighPack Systems is excited to introduce its V25 Bulk Case Filling System at PACK EXPO International 2024. Designed for mid-range, large-format filling applications, this robust system offers a highly efficient solution for automatically weighing and filling cases and totes with precision and speed, using the PrimoLinear® V-25 bulk weighing machine paired with a box indexing conveyor.

Engineered with ease of service and sanitation in mind, the V25 features advanced controls that seamlessly integrate with auxiliary machines, ensuring a smooth and synchronized operation. The system is equipped with a no-container, no-fill functionality and real-time communication between machines, optimizing cycle speeds for maximum efficiency.

The PrimoLinear V-25 boasts a 25L weigh bucket volume, a 304 stainless steel frame, and 304 stainless steel contact parts, making it ideal for a variety of food and non-food applications. It includes a quick-access drawer for vibrator controls and the load cell card, a single pan configuration, and a color touchscreen for intuitive operation. The system’s all-in-one tiltable hopper, along with tool-less removal of weigh buckets and funnels, simplifies maintenance and ensures quick, hassle-free changeovers.

Designed for versatility, the V25 can handle a wide range of products, including nuts, snack foods, candy, hardware, frozen foods, vegetables, fruits, meats, poultry, ingredients, spices, coffee, powders, granules, and pet food. Whether you're packaging bulk or foodservice items, this system can manage it all with precision.

Furthermore at its booth this year, the V25 box filling system integrates seamlessly with its sister company EndFlex's Boxxer-T 12 case forming machine, creating a complete box forming and filling solution for bulk and foodservice applications such as snacks, bakery goods (like tortilla chips, pretzels, and cookies), candies, and pet food.

Join WeighPack Systems/Paxiom at Booth N-5906 during PACK EXPO International 2024 to witness the power of the V25 Bulk Case Filling System and discover how it can streamline your bulk packaging processes.

VersaPak™ Compact Vertical Form Fill and Seal Machine

WeighPack Systems Inc. is featuring the VersaPak™, the most compact vertical form fill and seal machine, at PACK EXPO International 2024. Designed for convenience, flexibility, and efficiency, the VersaPak™ is a space-saving packaging solution perfect for businesses with limited floor space.

With its compact tabletop design, the VersaPak™ easily integrates into existing packaging lines, streamlining operations without requiring major modifications or investments. Ideal for industries ranging from e-commerce and hardware to food and home goods, the VersaPak™ is also an excellent choice for institutional packaging, particularly for school snacks, such as carrot sticks, celery sticks, apple slices, and orange slices, as well as candies, gummies, chocolates and more.

The VersaPak™ offers unmatched flexibility, the operators can hand-feed products directly or integrate the machine with a weighing scale for precise, automated filling. This versatility makes it a perfect solution for businesses of all sizes, accommodating both manual and automated packaging needs.

Capable of producing up to 20 packages per minute, the VersaPak™ fills pouches ranging from 2 to 8 inches (50 to 200 mm) in width. The machine uses non-proprietary roll stock film and can be set up on any tabletop or floor stand. Standard features include a large color touch screen, Omron PLC, bag forming collar with tube, recipe recall, and automatic bag length adjustment, providing an efficient and user-friendly experience.

Visit WeighPack/Paxiom at Booth N-5906 at PACK EXPO International 2024 to see the VersaPak compact vertical form fill seal bagging machine in action and learn how it can streamline your bagging process.