Next-gen equipment, affordable robotics that can work side by side with humans, and some interesting packages newly available to consumers—these were the highlights in the cosmetics and beauty care category at PACK EXPO International 2016.

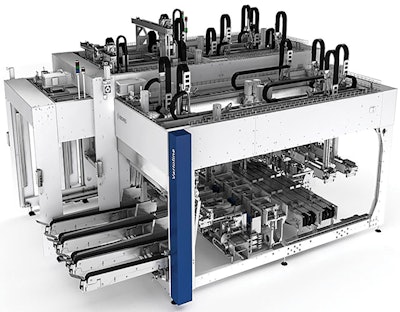

Weckerle, a large and long-time provider of lip pencils and lipstick filling machines, has upgraded their 15-year old technology. Weckerle introduced a totally revamped modular filling and assembly machine (model MS) that allows higher throughput and flexible capabilities to handle difficult formulations and different packages.

Traditionally, Weckerle offered an indexing turntable where all the operations took place—from filling the molds (cavities that create the waxy color sticks called “bullets) through chilling (by recirculating chilled liquid media around the molds) to de-molding and assembling the lipstick “bullets” to the packages.

The new design took the molds out from the rigid turntable and put them on a rectangular shaped indexing chain loop, three or more molds at a time. This configuration allows more molds to circulate in the process, more time to chill (by cold air) in three programmable refrigeration zones, and a wider temperature delta. The modularity and quick changeover was accomplished by incorporating a rack mounting system for all the stations on the machine. Detachable tooling also helps. I was told by Thomas Weckerle, the owner, that the new machine can also provide 20% more throughput than previous workhorse models.

To complement the filler, Weckerle also updated their robotic flexi-picker to unscramble and feed any lipstick, pencils, mascara, lip-gloss, or similar component (packages) from any component delivery method. The new flexi-picker is portable as well, making it a standard module for Weckerle.

High speed liquid filling lines handling multiple formats (such as shampoos and conditioners) require a great deal of flexibility. Krones demonstrated its latest all-in-one solution—the Varioline robotic end-of-the-line modular system (from collation to case packing to palletizing of cases). Krones Varioline (1) is designed to deal with a wide range of primary and secondary packaging variations, at up to 52,000 containers per hour. Every Varioline is different. This is because different modules can be combined to form a customized packaging line to meet the specific range of tasks as required. In addition to the standard version, all the modules are also available in compact versions for the low and medium performance ranges as well.

Some of the benefits are related to the way the equipment was constructed and configured. For example, since the modules all have the same mechanical components, maintenance and spare parts inventories are simple. Also, the complete packaging complex can be operated conveniently by just a single operator, and access is done through large doors. Another example is short change-over times. The tools are changed semi-automatically, and this guarantees reproducible results.

Cobots galore

The extreme possibilities of modularity and flexibility were introduced at PACK EXPO by companies displaying packaging applications utilizing “Collaborative Robots” (or “Cobots”). CPG manufacturers can now afford to get into robotic packaging by deploying these relatively inexpensive but amazingly simple-to-operate Cobots, most of which sell for $25,000 to $45,000.

Although invented 16 years ago, this family of robotic arms has only recently been deployed in the CPG arena (since 2008). Unlike conventional robot arms, this one doesn’t need to be surrounded by a fence to protect facility workers, and there is no need to hire programmers to set it up. Instead, the CPG manufacturer can use line workers to perform the setup in-house, on a touch pad, without any prior programming experience. Programming is easy. Simply move the robot arm to desired waypoints or touch the arrow keys on the easy-to-use touchscreen.

So what are “Cobots”? According to Wikepedia, a Cobot “is a robot intended to physically interact with humans in a shared workspace. This is in contrast with other robots, designed to operate autonomously or with limited guidance.” These cobots come in either one-arm formats, exemplified by Universal Robots and Kuka, or two-arm formats like those displayed by Rethink Robotics and Kawasaki.

These robots work side by side with people, so safety is imperative and an ISO standard was developed specifically for Cobots. In essence, the multi-axis robotic arm has built-in force sensors, and a slight resistance to their movement will stop them. To comply with the ISO standard, these robots are not designed to replace high speed industrial robots.

FlexLink, a part of the Coesia group, demonstrated a collaborative robot (UR 10 from Universal Robot) palletizer that unloaded cartons from a conveyor and placed them neatly on a two-pallet system (2). The UR10 robot is capable of 8 kg payload at up to 8 cycles/min. The system can be moved to any production line, and I was told that the total cost is about $80,000. Kuka displayed its relatively expensive cobot, one application of which is assisting surgeons in the performance of surgeries! Kawasaki demonstrated a typical kit assembly operation with two dual-armed cobots (3), and Rethink Robotics demonstrated a case-packing two-arm cobot integrated with a case-forming single-arm cobot.

Some of these cobots already come with integrated vision system (Rethink Robotics), allowing them to correct and adjust to real-time small changes on the production line. One use is to replace humans in dirty or dangerous environments.

Due to the “newness” of the collaborative automation approach, the challenge is to get the small CPG manufacturers to experiment and put cobot solutions to work. All in all, collaborative robots give the CPG manufacturer an affordable solution with all the advantages of advanced robotic automation but none of the traditional added costs associated with robot programming, set-up, and dedicated work cells from which operators must be shielded.

Let’s work together

A common theme at PACK EXPO was that of equipment suppliers providing total integrated solutions. Already mentioned was the Krones Varioline, where collating, case loading, and palletizing are all contained in one unit requiring one operator. Elsewhere, ESS Technologies demonstrated their model V30HS machine where ESS integrated the complete sequence of operations required to take individual (filled) items (in the show it was bottles), collate them, pack them into a corrugated case, and palletize the cases on a skid. The machine was capable of up to 22 cases/min. It was set up for 24 total formats with 13 different case sizes, and it also featured integrated serialization. Since the V30HS uses robotics and servos and can be changed over in 10- to 15 minutes, it may be attractive to co-packers who produce a wide variety of cosmetics products on the same line.

Others, like Serpa, Marchesini, and IMA, to name a few, are able to provide total solutions as a result of becoming vertically integrated through recent consolidations with smaller companies having complementary expertise; these consolidations make the new enterprise capable of providing a full equipment portfolio and, thus, full turnkey lines. Incidentally, IMA, which for a long time was focusing on pharma and food, has reorganized and has renewed interest in being a supplier to the cosmetics and beauty care industry. In fact, they just provided a complete hair color kit line to a major professional brand in Italy, from filling through palletizing, running at 200/ min).

Filling of cosmetics and beauty care products has its challenges. The bulk product itself can range from sticky & stringy to having no more viscosity than water to something that tends to drip from the filling nozzles. Moreover, the plethora of shades and bulk types requires quick changeover and thorough prevention of one product cross contaminating the one that comes next in the production schedule.

SERAC introduced a new valve system (4) to eliminate dirty products during the filling operation. This design is for the full range of bulk products to be filled. This patented nozzle has an ingenious built-in programmable suck-back design. The new technology can be incorporated into a number of SERAC standard platforms.

Quick changeover for filling systems is becoming a must for the cosmetics industry due to the constantly expanding range of colors and claim ingredients. IWK demonstrated its latest high-speed (200/min, 200 mL) flexible tube filler for hair conditioner type products. The metering is done by three lob pumps, pumps that lend themselves to being cleaned by a CIP system. The alternative is the nearly universal use of piston pump metering systems found in almost all the other tube fillers in the market. The pumps and nozzles are fitted with a receiving piping system allowing for very quick connection to CIP in order to run the flushing and sanitizing. The IWK tube filler also incorporates a simple, but very robust, method of picking and placing empty tubes into the holding fixtures on the machine.

HiBar, like others at PACK EXPO, demonstrated a seal-less ceramic valving system that not only facilitates very tight tolerance between the valve parts, thus eliminating potential blow by, but also makes it possible to handle liquids from water-thin to very viscous in the same valve. Utilizing ceramics helps in cleaning by CIP, and due to the tight tolerances contributes to filling accuracy. This type of valving is very useful for filling cosmetics products because the valve and pistons can work efficiently over a wide range of temperatures and viscosities, very common in the Cosmetics industry.

Developments in skin care

Also in evidence at PACK EXPO were some notable developments in skin care, a lucrative category for many cosmetics and beauty care suppliers, where tubes are often the packaging formats relied upon. Neopac presented an innovation called the Twist’n’brush™ tube. This is a variation of the Polyfoil®-Twist’n’use™ tube (5). The tube is fitted with extremely fine micro-bristles from GEKA Healthcare. The single-use tube meets the highest pharmaceutical requirements, and a multi-layer construction provides needed barrier quality. It’s suitable for liquid or semi-solid contents and can be temporarily resealed with the cap. It can be used with any lotions with active ingredients that need to be applied with precision, such as for facial and nail treatment, and for spots or scars on the skin.

There were other dispensing heads of interest, but perhaps the most intriguing one of all was Polyfoil Spin’n’dose. The fitment on the tube makes it possible to dispense fixed doses without the need for a pump. The spherical applicator head (flattened sphere/ball) can rotate 180 degrees, and built into it is a small cylindrical hole or channel with a small ball check that’s free to move from one side of the spherical applicator to the other side of the main ball, sealing against either end of the flattened ball. The dispensed amount is equal to the volume captured in the channel (less the ball). To apply, first the user turns the flattened ball 180 degrees, exposing the channel opening; then the tube is squeezed and the product in the channel is pushed out by the ball behind (pressure provided by squeezing the tube) until the ball check reaches the end of the channel and seals it.

Needless to say, these are only the highlights that one traveler down the aisles of PACK EXPO was able to uncover. It can’t help but make you wonder what we’ll see next year in Las Vegas.