In a heated presidential election season, we often hear about government spending, but when it comes to the development, contracting, and supply of vaccines, antivirals, diagnostics, therapeutics, and ancillary products, particularly for influenza, watching costs is a priority for Conceptual MindWorks.

Geoffrey Glauser is the project manager for Conceptual MindWorks, a consulting contractor and subject matter expert in support of the Manufacturing, Facilities, and Engineering Division of the Biomedical Advancement Research Development Authority (BARDA) in the office of the Assistant Secretary for Preparedness and Response (ASPR) within the U.S. Dept. of Health and Human Services (HHS).

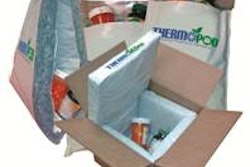

In assessing risk management in the packaging and shipping of temperature-sensitive medications, Glauser recommends fiscal responsibility and not “overengineer any solution and spending more than you need to get product from one point to another.”

During a Sept. 27 presentation, “Detailed Insight to Supply Chain and Cold Chain Risk Management” at the 10th Annual Cold Chain and Temperature Management Global Forum, Glauser offered multiple insights on the topic, including the following:

• Use Parenteral Drug Assn. Technical Report 58 as a reference to save time to plot shipping lanes. The report, which can be downloaded from this Web site aims to help manufacturers and distributors apply risk management to distribution practices.

• You can always under- or overengineer packaging. It’s important to understand what your product can withstand, develop stability data, determine secondary and tertiary packaging, and use patient impact as the key to anything you transport.

• Factor in economics, such as the value not only of the product itself, but also its market value, as well as insurance coverage. Take into account if your shipment is a one-time lane as opposed to a lane you will use often. Is it worth adding $50 for a shipping container if that investment results in no deviations or inspections?

• Assign risk priorities to each “touch point” in your process do determine priorities.

• The lack of training and awareness at different points in the supply chain is a big problem. Better to explain to a carrier or handler key issues up front to avoid potential problems.