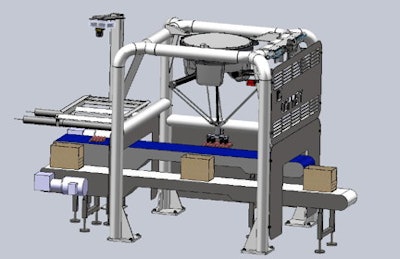

The Osprey is intended for installation in high sanitation areas of food packaging plants. Along with an innovative compact footprint, it is able to be placed at the discharge point of primary packaging systems. A vision inspection system allows the Osprey to track and handle randomly oriented and spaced products, and a vacuum leak detection system assures that only completely sealed packages are cased. Depending on the variables of individual primary packaging lines the Osprey can achieve throughput rates of 85 to 120 packages/mi. The Osprey can also be supplied with an integrated case erector and top and bottom case sealer. Provides primary and secondary packaging automation for meat, poultry, and cheese.