This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

They also feature a horizontal piston pump design that provides consistent, direct adhesive feed, and high efficiency design that uses 60% less energy and 50% less compressed air than comparable systems.

Options include automatic feed and low level detector.

Key benefits include an innovative tank construction that ensures uniform melt temperatures with no hotspots, char, or waste, a horizontal piston pump design that provides consistent, direct adhesive feed, and high efficiency design that uses 60% less energy and 50% less compressed air than comparable systems. The Micron+ has a compact footprint that enables easy installation on existing packaging equipment and on traditional hot melt tank stands. Designed for ease of operation and operator safety, its extra-large tank lid opens completely to simplify refills and the Cool Touch housing limits heated surfaces. Time-saving maintenance features include easy access to all components via control panel door, slide-rail opening pump access, and lift up tank housing. The Micron series’ outstanding union of form and function was honored with the “Red Dot” design award and brings a new level of productivity to packaging lines worldwide.

The Micron+ has a purchase price 30% lower than competitive hot melt adhesive units, and a comprehensive 2-year parts and service warranty that is unmatched in the industry. Micron systems and components are interchangeable with other hot melt systems and locally available to North American packagers through the Meler network of sales/service and distributors across the United States. “Meler’s Micron adhesive systems have a solid record of success on packaging lines throughout Europe and Asia, including high speed carton and case sealing, package and bag labeling, beverage bottle and can labeling, wraparound packaging, and end-of-line and product assembly applications. The new Micron+ series adds industry 4.0 connectivity to the many benefits for our customers, and we are happy to bring this technology and innovation to North American markets,” said Khal Anis, senior vice president, Meler USA.

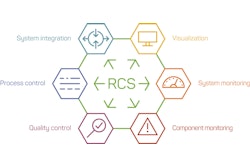

The Micron+ melds sophisticated hot melt technology with highly intuitive and user-friendly operation, ensuring seamless integration on the packaging line with reduced operator training time and costs. The 7 in. touchscreen control panel has a menu interface that provides quick access to monitor real time production data, program glue head operation, and check equipment status and maintenance. Industry 4.0 connectivity allows full integration with packaging machine HMIs and secure WiFi connection to smartphones or tablets. Multiple communication protocols including Ethernet-IP, Modbus RTU, Profibus, and Profinet are available to provide full compatibility with existing equipment and factory automation networks.