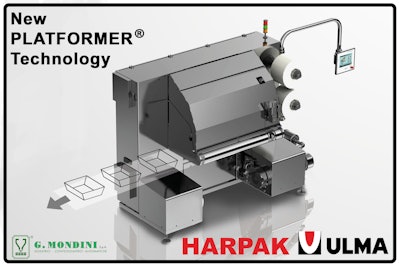

Thermoformer/tray sealer

The packaging world has always been divided into either thermoforming or tray sealing lines, the former producing value packages, and the latter making higher quality packages with greater flexibility. This technology cuts the tray footprint before the forming process occurs, reducing scrap to just 1%. An additional benefit of this innovative process is that the tray format changeover time is less than 10 min. with only two components needing to be changed. With the option of using trays made in line or pre-made, packagers now have more options .

Companies in this product

Videos from Harpak-ULMA Packaging, LLC.