The enclosure seats against the rim of a hopper or flange of downstream equipment, and is equipped with an exhaust port for dust collection, and a hinged door with inspection window.

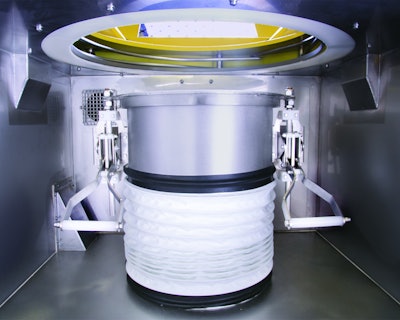

The top of the enclosure contains a circular opening that allows passage of the bag spout to the equipment connection point. The flat bottom of the enclosure supports a Tele-Tube telescoping tube that pneumatically raises a Spout-Lock clamp ring which connects the clean side of the spout to the clean side of the equipment.

Allowing the telescoping tube to descend under its own weight maintains constant downward tension on the spout as the bag empties and elongates. The Flow-Flexer bag activators raise and lower opposite bottom edges of the bag at timed intervals to loosen compacted materials, promoting material flow and complete discharge from the bag.

The enclosure contains incidental leakage of fine powders from seams in the bag, as well as material released from bag spout folds during connection and disconnection activities. Associated dust is vented through the sidewall-mounted port to an optional Bag-Vac dust collector or plant bag house, preventing contamination of the environment.

For applications requiring retying of partially empty bags, an optional Power-Cincher pneumatically-actuated flow control valve cinches the spout concentrically on a horizontal axis for easy tie offs, and vertically in a tight zigzag pattern to prevent leakage of powders.

Constructed of stainless steel finished to food, pharmaceutical, and industrial standards, the Dust Hood is offered on all Flexicon dischargers including models requiring forklift loading of bulk bags, models that load bags using an electric hoist and trolley, half-frame dischargers that require a forklift or plant hoist, and split-frame dischargers for forklift loading of bags in low headroom areas. All can be integrated with the company’s mechanical, pneumatic, and tubular cable/disc conveyor systems, and are available with controls for automated weigh batching directly from bulk bags.