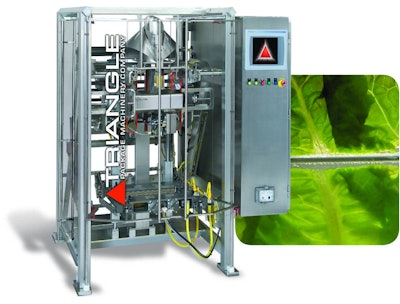

Ultrasonics technology is suitable for leafy produce, cheese, confectionery, and other applications that require 100% seal integrity for an airtight product. With Ultrasonic technology, the bagger’s sealing jaws can seal right through product and push it completely out of the sealing area, resulting in less headspace and improved material savings. On average, traditional heat seals measure 3/8 in., while Ultrasonic seals can be as narrow as 2 mm–a potential savings of 50-80% in the sealing area alone.

Additional benefits include less downtime and improved OEE, as well as significantly reduced leakers and rejects due to product in the seal. In some industries, it may reduce or eliminate the requirement to manually inspect 100% of bags for leakers, resulting in improved labor savings and higher throughput.