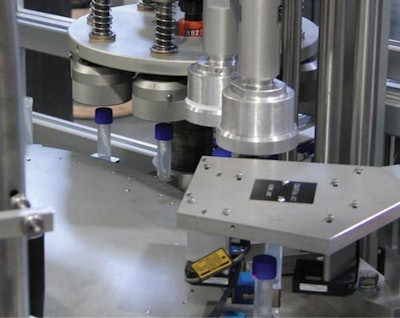

Able to operate at speeds up to 120 bottles per minute, the unique design allows caps to be handled with precision to reduce the risk of dropped or skewed caps. A two-stage torque system first uses a unique “donut” clamp to place the cap with complete accuracy and applies the first level of torque to secure the cap. The container indexes to the second stage where the final torque is applied to the exact specification. The use of servos enables the system to apply a precise amount of torque to the cap.

Companies in this product